- Home

- Sustainability

- Environment

- Utilization of Sustainable Forest Resources

Utilization of Sustainable Forest Resources

Utilization of Japanese Timber

In Japan, the public and private sectors are working together to increase the self-sufficiency rate of domestic wood in order to achieve carbon neutrality and a decarbonized society by 2050.

The Sumitomo Forestry Group promotes the use of domestic timber and contributes to sustainable forest management in Japan and the revitalization of the local timber market.

Establishment of an Industrial Complex to Promote the Use of Domestic Timber

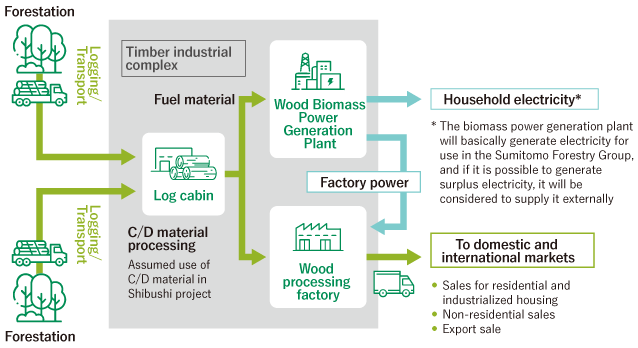

The timber industrial complex promoted by Sumitomo Forestry as part of its long-term vision, "Mission TREEING 2030," is a key initiative aimed at maximizing the added value of timber, promoting the use of domestic timber, and advancing cascade utilization.

Project overview

Aerial view of the Yotsukura Plant under construction (Iwaki City, Fukushima Prefecture)

As the first initiative of the Timber Industrial Complex, a joint venture company, Kowanomori Co., Ltd., was established in Iwaki City, Fukushima Prefecture, in November 2023. We are currently constructing a new factory within the Yotsukura Core Industrial Park, aiming to begin operations in March 2026.

In February 2022, we signed a basic location agreement with Shibushi city in Kagoshima Prefecture, aiming to construct a new factory that will produce high-strength structural materials suitable not only for residential buildings but also for non-residential construction.

Amid the declining trend in new housing starts in Japan, the timber industrial complex plays a vital role. The initiative aims to increase the usage ratio of domestic timber and establish a stable supply system for domestic structural materials, in order to mitigate supply uncertainties of imported structural materials for both residential and non-residential buildings in the event of external disruptions such as the "wood shock."

Sumitomo Forestry aims to improve productivity in wood manufacturing and ensure a stable supply of wood products, thereby strengthening price competitiveness. In addition, we will promote the creation of employment opportunities for forestry workers by increasing the added value of wood, the use of domestic timber, and contribute to decarbonization by increasing the period of carbon storage.

*By cascading the use of wood through applications such as timber use, energy use, and chemical use, the value of wood is enhanced, enabling long-term carbon storage

Promoting the Use of Unused Forest Resource

Unused forest resource is left-over wood not suitable as a building material or wood from thinning in forests. Although demand for pulp for papermaking has been sluggish, wood biomass power generation plants are operating in each area and the demand for wood biomass is growing following the adoption of the Feed-in Tariff for Renewable Energy law (FIT). By using unused forest resource, we can expect an effective increase in the value of forests while also promoting renewable energy. In fiscal 2024, the Sumitomo Forestry Group used 404,000 tons of unused domestic forest resource at its power plants. We will continue to work on building up systems for the efficient, stable collection of unused forest resource.

Amount of unused forest resource from domestic forest (2024)

404,000tons

Unused forest resource

- Click here for related information

First Use of Domestic Japanese Cedar for Exterior Material in Condominiums

The exterior decorative material "SUSTIMBER Eaves eave soffit," developed by Sumitomo Forestry, has been adopted in the condominium "Park Homes Johoku Central Park" (Itabashi-ku, Tokyo) by Mitsui Fudosan Residential Co., Ltd. "SUSTIMBER" is an exterior decorative material that utilizes domestically sourced Japanese cedar and is coated with a protective paint to ensure the wood's weather resistance, maintaining the building's aesthetic appeal for a long period. It is used on the eave soffit of the entrance and balconies of the units in the condominium.

We will continue to leverage the research and knowledge accumulated at the Sumitomo Forestry Tsukuba Research Institute regarding wood, and promote the use of wood and woodification not only in our own properties but also in other companies' multi-family housing and non-residential facilities.

SUSTIMBER - Eaves soffit

Balcony Using SUSTIMBER - Eaves soffit

Utilization of Wood Resources

Wood Resources from Chips

The Sumitomo Forestry Group contributes to resource recycling through its wood chip operations, whereby offcuts generated during the wood milling process and wood waste from new housing construction and demolition sites are turned into wood chips to be used as a raw material for products such as paper and particle board, and also as a fuel for power-generating boilers or other equipment.

As demand for the supply of fuel for biomass power generation continues to rise, we aim to further expand the handled volume of fuel applications by using not only offcuts and wood waste but also thinned wood and other unused forest resource.

Started Wood Pellet Manufacturing and Sales Business in Indonesia

Sumitomo Forestry has entered the wood pellet manufacturing and sales business in Indonesia, and in January 2025, commercial production began at PT. Biomassa Lestari Nusantara (BLN), a joint venture established with PT. Dharma Energi Investama in Indonesia.

The BLN factory collects raw materials that have previously had little utilization value, such as wood offcuts and unused small-diameter logs from nearby wood processing factories and forests, and manufactures wood pellets. All manufactured pellets are purchased by the Sumitomo Forestry Group and sold primarily to biomass power generation plants in Japan.

The production volume in the first phase is 60,000 tons per year, and an increase to 120,000 tons per year is planned for the second phase around 2026.

The Sumitomo Forestry Group promotes cascade utilization, making full use of wood without waste through its business activities, maximizing the value of wood to advance decarbonization.

Exterior of BLN Company Factory

Scene of the First Shipment

- Home

- Sustainability

- Environment

- Utilization of Sustainable Forest Resources