- Home

- Sustainability

- Environment

- Responding to Climate Change

- Mitigation of Climate Change

Mitigation of Climate Change

- Sales of ZEH and LCCM Homes

- Features of Sumitomo Forestry's ZEH and LCCM Homes

- Renovating to Improve Function and Asset Value

- Development of Environmentally-conscious Housing Overseas

- Visualization of CO2

- Promotion of the Renewable Energy Business

- Visualization in Investment

- Investment in Japan Green Investment Corp. for Carbon Neutrality

Sales of ZEH and LCCM Homes

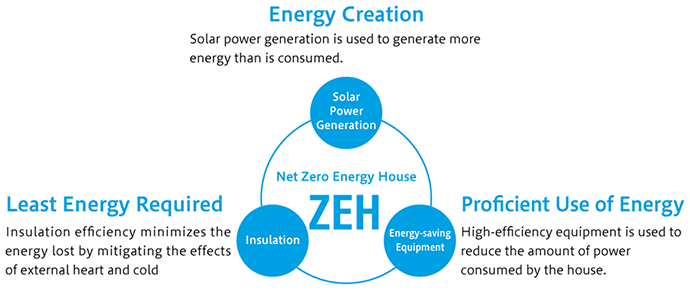

Households account for 15.3%*1 of Japan’s CO2 emissions, and to reduce this, nationwide efforts are underway to promote the adoption of ZEH (Net Zero Energy Houses) in new residential construction.

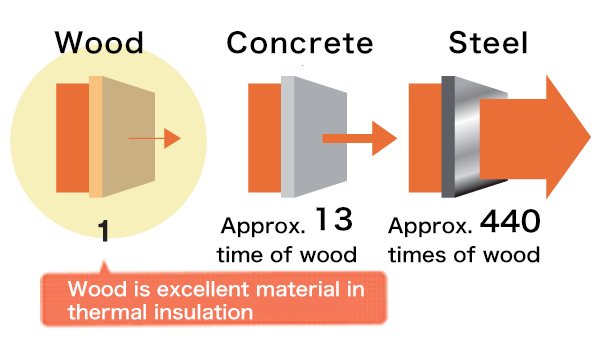

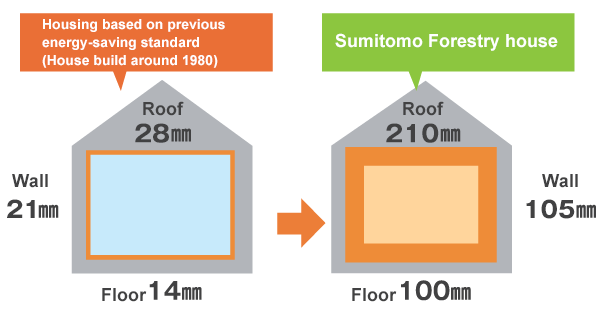

In the Sumitomo Forestry Group’s Mid-Term Sustainability Targets Phase 1 (2022–2024), we set a goal of achieving an 80.0% ZEH order ratio for new custom-built detached houses by fiscal 2024. To reach this target, we have utilized wood with excellent insulating properties as a structural material, and we have adopted our unique design approach, Ryouonbou, which harnesses natural elements such as wind and sunlight. Through these efforts, we have continued to provide homes that offer year-round comfort. By combining our expertise in utilizing the characteristics of wood and the blessings of nature with technologies for reducing energy consumption, such as improvements in thermal insulation, and the adoption of energy-saving equipment and technologies for the smart use of energy, such as equipment for generating and storing energy and HEMS*2, we are able to improve energy efficiency in the home and reduce CO2 emissions during occupancy. The ZEH order ratio for fiscal 2024 was 79.3%*3, a decrease of 0.4 percentage points compared to the previous fiscal year.

In April 2022, the Company launched its "LCCM (Life Cycle Carbon Minus) homes. LCCM homes reduce CO2 emissions during construction, occupancy, and demolition, and they also generate renewable energy using solar power generation, etc. to achieve negative CO2 emissions over their entire life cycle. The wood used as a structural material in Sumitomo Forestry Homes absorbs CO2 through photosynthesis as it grows, and it continues to store carbon even after it has been harvested. In addition, our proprietary Big Frame (BF) construction method is characterized by its flexibility, making it easy to renovate floor plans. This contributes to long-term carbon storage by extending a building’s lifespan. Sumitomo Forestry’s LCCM homes leverage the advantages of wood to reduce total CO2 emissions throughout construction, renovation, and demolition. By utilizing renewable energy sources, such as solar power generation systems, renewable energy equipment, and thoughtful designs, these homes achieve LCCM.

Since 2022, we have started to make proposals based on the "Environmental Contribution Presentation Sheet" for houses that nurture forests in order to promote the spread of LCCM homes. By making it possible to easily calculate carbon storage and the area equivalent to reforestation at the design stage, we are making the environmental contribution visible. In order to advocate these initiatives, "environmental contribution" is posted at each exhibition hall.

The Sumitomo Forestry Group will contribute to the realization of a decarbonized society through the provision of homes, including LCCM homes.

*1From the Ministry of the Environment, "Greenhouse Gas Emissions and Absorptions in Fiscal Year 2022 (Detailed Report)"

*2Home Energy Management System. A system whereby residents can visualize the amounts of energy they generate and use

*3Including Nearly ZEH, Small ZEH Oriented, Heavy Snow ZEH Oriented

Percentage of orders for ZEH type houses out of new custom-built detached housings* (FY 2024)

79.3%

*Indicators for Evaluation of Mid-Term Sustainability Targets Phase 1 (2022–2024) (Data collection period: January to December 2024)

LCCM housing model home "Yonago (Wooden Houses Lab.) model home"

- Click here for related information

Features of Sumitomo Forestry's ZEH and LCCM Homes

Wooden Houses with Superior Insulation

If the thermal conductivity of wood is 1, the thermal conductivity of concrete would be almost 13 and steal upwards of 440. Wood as a material is a superior insulator to mitigate the transfer of heat. In addition, Sumitomo Forestry uses high-performance 24K glass wool thermal insulator (high-end product) based on its own unique standards.

Comparison of Materials by Thermal Conductivity

Unique Standards of Thermal Insulators of Sumitomo Forestry

Adoption of "360° TRIPLE Insulation Standards"

Sumitomo Forestry has adopted 360° TRIPLE Insulation as a standard that enhances the insulation efficiency of new custom-built detached houses (excluding fireproof specifications). In addition to offering high-performance thermal insulation materials, the standard provides all-around insulation for buildings as a whole from structural members to windows with high thermal performance to realize affordable yet comfortable lifestyles.

360° TRIPLE Insulation creates a living space that stays cool in the summer, warm in the winter and increases energy-saving performance. This specification corresponds to ZEH level of BELS* (Building Energy Saving Performance Labelling System) promoted by the government.

Sumitomo Forestry applies for BELS for all of new custom-build detached houses. BELS is a labeling system with which a third party evaluation organization evaluates and certifies the energy efficiency of new and existing structures using an index indicating the energy performance and asset value of each building. Our initiative strives to make Sumitomo Forestry the first major housing manufacturer to have every building BELS-certified. In fiscal 2024, the BELS certification rate (at the start of construction of the main unit) was 99.4%. Sumitomo Forestry homes with their enhanced insulation performance provide residents with the peace of mind and comfort that comes with BELS certification.

*One of the third-party certification systems based on "Guidelines for energy efficiency Labeling System for Sales and Rental of Buildings under building section of Act on the Rational Use of Energy" established by Ministry of Land, Infrastructure, Transport and Tourism. The system is operated by the Association for Evaluating and Labeling Housing Performance. This system objectively evaluates energy efficiency to label star rating. BELS stands for the Building-Housing Energy-efficiency Labeling System

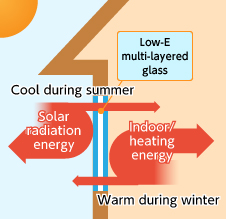

Adoption of Glass with Superior Heat Insulation Properties

Windows cause the greatest loss of heat in living spaces. Shielding interior spaces from heat in the summer and preventing heat from escaping in the winter is vital. As windows cause the largest heat loss, Sumitomo Forestry uses low-E multi-layered glass with argon gas inside. Argon gas is injected between the multi-layers of glass to mitigate heat transfer to the air while the panes are coated with special metal film. The superior thermal insulation and insulation properties shield interior spaces from heat in the summer and prevent heat from escaping in the winter.

Insulation using low-E multi-layered glass

- Click here for related information

Trends in Installation Rates of Environmentally-conscious Equipment (based on number of houses)

| FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|

| Solar power generation systems | 68.9% | 78.1% | 78.9% | 77.7% |

| Ene-Farm units | 25.5% | 20.5% | ‒ | ‒ |

| Eco One | 19.4% | 24.4% | ‒ | ‒ |

| Ene-Farm & ECO ONE* | ‒ | ‒ | 43.9% | 40.3% |

| Environmentally conscious equipment installation rate | 78.2% | 84.6% | 86.2% | 84.1% |

*From fiscal 2023, combined installation rate of Ene-Farm and Eco One is shown

Converting rental apartment house to ZEH and sales of wooden apartments started

Sumitomo Forestry is promoting ZEH-M (Net Zero Energy Mansion)*1 in all of its Forest Maison apartments to achieve a comfortable indoor environments and significant energy efficiency performance. ZEH-M with improved energy efficiency based on specifications for the ZEH level of BELS promoted by the government will be acquired for all buildings. We will also promote the installation of solar power generation systems to reduce CO2 emissions during daily life.

In May 2023, Forest Maison, a commercial real estate development, adopted 360° triple insulation, which is the same as that of detached houses products. It achieves performance that exceeds ZEH-M Oriented standard, which significantly improves the insulation performance of the home, maintains a comfortable indoor environment by installing highly efficient equipment, and reduces the primary energy consumption of the entire building, including common areas, by 20% or more*2. Furthermore, in November 2023, we launched the wooden apartment "Forest Maison GRANDE" for rent, which promotes zero energy consumption for each dwelling unit. With less CO2 emissions (embodied carbon) at the time of manufacturing and construction than RC and steel apartments and the carbon storage effect of wood, wooden apartments are characterized by their lower environmental impact.

*1Acronym for Net Zero Energy House Mansion. An apartment house that improves the insulation and energy efficiency performance, generates energy through solar power generation, etc., and achieve a "zero" balance of primary energy consumption (air conditioning, hot water supply, lighting, ventilation) per year. ZEH standards for multi-family housing set by the government, which are classified into four categories according to the primary energy consumption reduction rate: "ZEH-M," "Nearly ZEH-M," "ZEH-M Ready," and "ZEH-M Oriented"

*2Comparison with the standard primary energy consumption for "heating," "cooling," "ventilation," "lighting," and "hot water" according to the 2016 Energy Efficiency Standards

Exterior image of "Forest Maison GRANDE"

Launched the commercial building brand "The Forest Barque"

In May 2024, we launched "The Forest Barque," a wooden commercial building brand. Leveraging a supply chain capable of delivering approximately 8,000 units of Sumitomo Forestry homes annually, we have adopted our proprietary Big Frame Structure method, which also supports systematized design. It offers excellent seismic resistance and allows for highly flexible designs, making it suitable for offices, clinics, and retail stores. We propose high-quality spaces rich in natural wood ambiance by leaving the structural framework exposed (The wood is visible). With high insulation specifications, it meets ZEB (Net Zero Energy Building)* standards, and it reduces CO2 emissions during building operations (operational carbon).

*It is a building that achieves net zero annual primary energy consumption through energy conservation and energy creation while maintaining a comfortable indoor environment.

Exterior image of "The Forest Barque"

Renovating to Improve Function and Asset Value

Sumitomo Forestry Home Tech promotes energy-saving, vibration control, and seismic renovation (performance-improving renovation) for houses built before the revision of energy-saving standards in 1999 and the seismic resistance standards in 2000. Regarding energy-saving renovation, we announced development of an "insulation renovation work proposal system" using AI to improve energy efficiency of existing houses in December 2023. We aim to improve residents' quality of life and realize well-being by improving living environment such as maintaining a comfortable state for a longer period with less primary energy by promoting insulation renovation work.

In recent years, the need for safe and secure housing has been increasing due to concerns over intermittent earthquakes. We will provide safe and secure housing by actively promoting vibration control and seismic renovation that are centered on the "dual construction method for vibration control and seismic resistance,"*1 which uses our original vibration-control dampers.

We will contribute to realization of a decarbonized society by promoting renovation with improved performance that combines energy conservation, vibration control and seismic technology to improve comfort of houses, reduce primary energy consumption, and extend lifespan of buildings.

*1This is a construction method using damping devices with hydraulic dampers which are also used in high-rise buildings, and a "seismic damper model S" developed for 2-story houses using conventional post-and-beam construction method. It absorbs and reduces shaking during earthquakes, prevents the deformation of buildings, and is also effective against repeated aftershock vibrations

Environmentally conscious renovation

In recent years, abnormal weather events and massive earthquakes have become major concerns. Promoting renovations that improve seismic capacity and insulation efficiency contributes to extending a building’s lifespan, leading to long-term carbon storage.

Sumitomo Forestry Home Tech has set the goal of "improving the rate of orders for environmentally conscious renovations" in its Mid-Term Sustainability Targets Phase 1 (2022–2024), with fiscal 2024 as target year.

We are working to "productize" our remodeling proposals. Our remodeling plans include three services: space proposals, performance proposals, and safety support. In fiscal 2024, the order amount ratio for the four types of work (seismic construction, structural reinforcement work, heat insulation renovations, and smart material*2 installation) on general housing (other than owners of Sumitomo Forestry homes) reached 79.1%, an increase of 3.9 percentage points from 75.2% in fiscal 2023.

On the other hand, the total order amount ratio for the four types of work (seismic construction, exterior work, heat insulation renovations, and smart material installation) on Sumitomo Forestry homes reached 64.1%, an increase of 2.3 percentage points from 61.8% in fiscal 2023.

With fiscal 2027 as the target year, the Mid-Term Sustainability Targets Phase 2 (2025–2027) also sets a goal to increase the order rate of environmentally conscious renovations, and we will continue to promote renovation proposals that are environmentally friendly.

*2Solar power generation systems, storage batteries, Ene-Farm units, etc.

Development of Environmentally-conscious Housing Overseas

The United States

In the United States, we promote obtaining ENERGY STAR certification. ENERGY STAR certification is an energy efficiency rating program promoted by the EPA (the U.S. Environmental Protection Agency). Standards are established for each climate zone in areas such as thermal insulation efficiency, heating and cooling systems, airtightness, water heaters, lighting, and home appliances.

Some U.S. builders within the Sumitomo Forestry Group have obtained ENERGY STAR certification, and they contribute to reducing environmental impacts by providing highly energy-efficient homes.

MainVue, operating in Washington State, is promoting the sale of environmentally conscious homes with even higher performance, and all homes delivered in 2023 met the U.S. Department of Energy’s Zero Energy Ready Home*1 standard. MainVue homes optimize energy efficiency through the installation of electric-powered HVAC systems*2, maintain healthy indoor air quality in all rooms with energy recovery ventilation systems, and keep indoor temperatures comfortable using insulated windows with a U-value*3 of 30.25 or lower. MainVue homes are environmentally friendly and also provide comfortable living for the occupants.

*1These houses are designed to have high energy-saving performance and for the installation of solar panels. When solar panels are installed, annual electricity consumption can be offset by the amount of electricity generated

*2HVAC stands for "Heating, Ventilation, and Air Conditioning," and it refers to systems designed to maintain a comfortable indoor environment within buildings

*3Thermal transmittance (U-value). A lower value indicates higher thermal insulation performance

MainVue Home

Australia

Henley Properties, as a major home builder company in Australia engages with a variety of initiatives to reduce environmental impact, including development of the first zero emission house*1 for general consumer. In addition, all-electric homes equipped with solar panels, which Henley is promoting for sale, can save up to 75% on utility costs and reduce CO2 emissions by up to 100% when occupied.

It was also the first company that launched a new residential product, "Mainvue Collection," that complies with the Energy Rating*2 7-star standard. By enhancing insulation performance and improving energy efficiency through layout modifications, the MainVue Collection has achieved a 7-star rating. Henley will continue to be a driving force to improve energy efficiency of country's housing industry.

*1Environmentally-conscious housing expected to have an energy-saving effect of more than 70% compared to conventional housing

*2An evaluation metric of the energy burden for heating and cooling the inside of a building in Australia. Insulation, windows, the type, size and orientation of the building, and the climatic zone are all items included in this metric

Houses from the MainVue Collection

Asia

Sumitomo Forestry strives to standardize decarbonized designs in Indonesia and other Asian countries. In detached housing business, we are developing environmentally sound houses and working to acquire "EDGE certification*1", which evaluates environmental performance of buildings.

Indonesia

In the residential property development business in Depok City, near Jakarta, Indonesia, Sumitomo Forestry will provide comfortable and highly safe homes that are resilient against disasters by implementing the design and construction technologies it has cultivated both domestically and internationally. We are proceeding with environmentally sound development, including the installation of solar panels as standard.

Besides, we launched a spec home business in Bogor City of India that uses solar panels as standard equipment in 2023. In spec home business in Bogor City, based on design approach of "Ryouonbou natural heating and cooling system*2" which utilizes knowledge of Japan's housing business, we create a comfortable living environment by shielding sunlight with deep canopies and eaves, and adjusting temperature inside and on the premises by utilizing natural ventilation and planting. In addition, instead of bricks, which emit a large amount of CO2 during manufacturing, we use autoclaved aerated concrete blocks,*3 which have a low environmental impact, to reduce embodied carbon during construction. These initiatives have led to us obtaining EDGE Advanced certification for the projects in Depok City and Bogor City. We also obtained EDGE certification for the residential property development business in Makassar City, Sulawesi Island, Indonesia, which started in 2021. We will continue to accelerate the standardization of carbon neutral design in Indonesia and other Asian countries.

*1A building environment certification developed by the World Bank's IFC and used mainly in developing countries. It is necessary to reduce energy consumption during construction, energy and water consumption in life by 20% or more compared to buildings with local general specifications. If energy consumption is reduced by 40% or more under the same conditions, EDGE Advanced certification is granted

*2A design method developed by Sumitomo Forestry that utilizes natural blessings of wind, sun, and greenery to create comfort of summer breezes and winter sunshine. While considering surrounding environment of each site, the design leverages characteristics of wind flow, sunshine and greenery to create a comfortable home that does not depend on heating and cooling equipment

*3Autoclaved lightweight aerated concrete refers to high-temperature, high-pressure and high-humidity curing

Image of development at Depok City

Vietnam

Since 2024, Sumitomo Forestry has been participating in a large township development project in Binh Duong Province through a collaboration with Kumagai Gumi Co., Ltd., NTT Urban Development Corporation, and the local major real estate developer Kim Oanh Group (hereinafter referred to as KOG).

KOG has extensive experience in the development of residential condominiums for sale in southern Vietnam and has shown a strong interest in decarbonization technologies and wood construction. Sumitomo Forestry combines its design expertise and use of low environmental impact building materials cultivated through its domestic and international housing businesses, Kumagai Gumi's knowledge in large-scale construction and civil engineering, and NTT Urban Development's diverse real estate development experience both in Japan and abroad, as well as the ICT expertise of the NTT Group, to aim for sustainable community development and contribute to realizing a carbon-neutral society in Vietnam.

Development Image in Binh Duong Province

Visualization of CO2

Research & Development

Sumitomo Forestry is working to visualize the environmental contributions of wooden construction and the use of wood-based materials, such as their effectiveness in reducing embodied carbon, in order to clarify and enhance their value and contribute to the realization of a decarbonized society.

In addition, by scientifically elucidating the shared benefit of forests, particularly the life cycle of CO2 absorption and emission, Sumitomo Forestry aims to enhance the asset value of the forests owned and managed by the Group, promote decarbonization, and establish a circular bio-economy. To this end, it is conducting research to estimate the amount of carbon storage in forests by tree species, site conditions, and forest management methods.

Estimating Carbon Storage in Existing Wooden Buildings

In October 2022, Tokyo University of Agriculture and Technology has published a study in the open access journal Scientific Reports on a method for estimating carbon storage in wooden buildings constructed by the private sector over the past 50 years.

At the 17th Conference of the Parties to the United Nations Framework Convention on Climate Change (COP17) held in 2011, it was agreed* that changes in carbon stocks within Harvested Wood Products (HWP) should be accounted for as greenhouse gases absorption or emissions by each country. HWP are important for climate change mitigation because they continue to store carbon after they are harvested from the forest.

In order to make effective use of HWP, it is first necessary to accurately determine their carbon storage. This study focused on wooden buildings, which store the most carbon of all HWP applications, and it examined methods for estimating HWP carbon storage in buildings.

Building data was provided by Sumitomo Forestry, and the estimation method was jointly verified with Tokyo University of Agriculture and Technology. The results of this research have made it possible to understand and estimate the carbon storage capacity of wooden buildings with greater accuracy.

The study focused on wooden houses built by Sumitomo Forestry from 1969 to the present. Using the number of existing houses by year of construction and the number of houses built each year, the researchers calculated the housing retention rate and developed the model that best fit this data.

Using this model, the carbon storage of existing wooden houses, calculated by subtracting the demolished buildings from the total number of wooden structures built since the start of the housing business through fiscal 2024, is estimated to be 7.87 million tons of CO2. This corresponds to slightly more than half of the carbon storage of approximately 14.05 million tons of CO2 held in Sumitomo Forestry’s domestic company-owned forests, which cover about 48,000 hectares. It is believed that Sumitomo Forestry’s wooden houses function as urban forests that store CO2 over the long term.

*In the second commitment period of the Kyoto Protocol, the rule to evaluate and account for changes in the carbon content of HWP (carbon storage effect) is permitted. The HWP calculation rules apply to "wood," "wood panels," and "paper" produced from cultivated forests under "forest management" in Japan

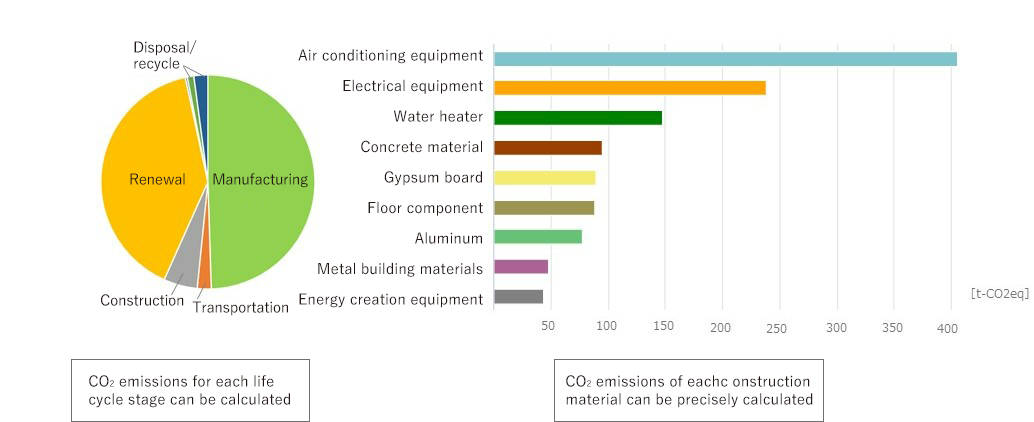

Visualization of CO2 emissions throughout the entire supply chain

Visualization of embodied carbon

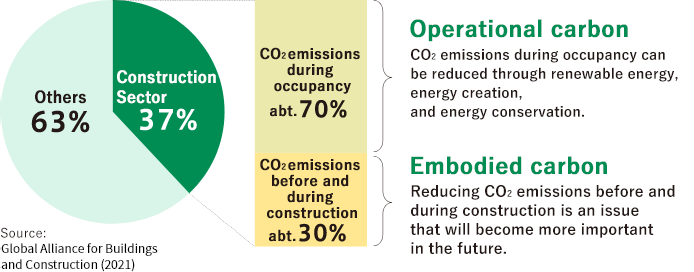

It is reported that the construction sector accounts for about 37%* of global greenhouse gas emissions. About 70% of that is operational carbon, with the remaining 30% being embodied carbon. Operational carbon has been reduced through the spread of ZEH and ZEB, and the urgent issue going forward is to reduce embodied carbon. When calculating CO2 emissions of embodied carbon, it is necessary to calculate the environmental impact throughout the entire life cycle of a building.

In August 2022, Sumitomo Forestry began selling the Japanese language "One Click LCA", software that visualizes CO2 emissions and other data from buildings, as the sole distributor in Japan.

"One Click LCA" is used in 170 countries, mainly in Europe, and is compatible with international ISO standards and more than 60 green building certifications worldwide. It is possible to precisely calculate CO2 emissions (embodied carbon) from procurement of construction materials used for buildings, transportation, construction, repair, disposal to recycling.

EPD acquisition support

CO2 emissions from products at stage of procurement of building materials have the greatest impact on CO2 emissions from buildings. As a mechanism for visualizing CO2 emission amount of a product, there is an environmental labeling system EPD (Environmental Product Declaration). EPD is an abbreviation of Environmental Product Declaration, which is an ISO-compliant environmental certification label for calculating environmental impact of the entire life cycle of a product from procurement of raw materials to disposal thereof, and quantitatively indicating environmental load of the product, including amount of CO2 emissions.

In February 2023, Sumitomo Forestry started a business of acquiring and supporting an environmental labeling system EPD for lumber and building material manufacturers. By utilizing the "EPD generator" provided by One Click LCA, EPDs of all products related to construction can be smoothly acquired. As of the end of December 2024, more than 20 products have obtained EPDs with our support.

In addition, Sumitomo Forestry has started a CO2 calculation service for buildings by "One Click LCA" for tenants, developers, and construction companies. In response to increasing demand for LCA in building industry, we utilize knowledge of Sumitomo Forestry's LCA experts to calculate and report the calculation results for each project. Currently, we have received many requests for calculation from customers. As of December 31, 2024, we have completed LCA calculations for more than 100 buildings.

Sumitomo Forestry is promoting decarbonized designs in Japan’s construction industry through the spread of "One Click LCA" and the "EPD generator."

*Source: Global Alliance for Building and Construction (2021)

Global CO2 Emission Rates by Industry

Example of calculation with "One Click LCA"

*CO2 emissions for each life cycle stage can be calculated

*CO2 emissions of each construction material can be precisely calculated

*Source: The above graph is the result of our own calculations using "One Click LCA" based on the data published in the "Fiscal 2007 Report on the CO2 Reduction Demonstration Work for the Promotion of Wood Use and Energy Saving" released by the Forestry Agency in March 2008

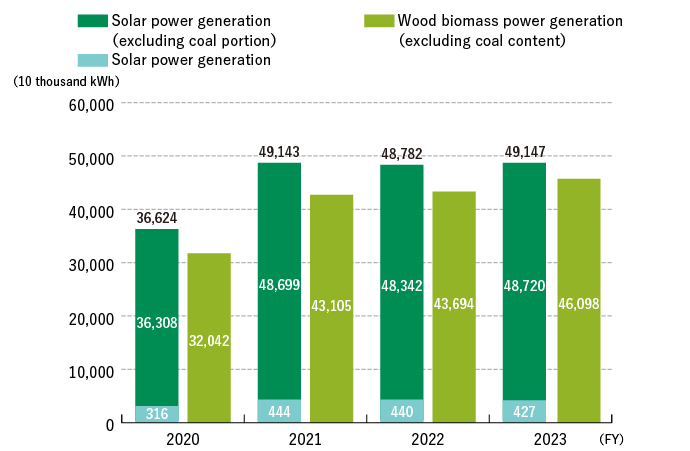

Promotion of the Renewable Energy Business

The Sumitomo Forestry Group is advancing renewable energy generation businesses, including solar power generation as well as wood biomass power generation that chips and uses scrap construction wood in addition to unused forest resources and other such materials as fuel. In 2024, the total amount of electricity generated was 499.72 million kWh (including from coal), a decrease of 1.6% from 2023.

Effect of CO2 emission reduction through power generation in fiscal 2024*

211,341t-CO2e

*CO2 emission reductions compared to the electricity purchased from power companies. These emissions are calculated using the CO2 emission coefficients of mainly Hokkaido Electric Power and Tohoku Electric Power. The reason for the increase compared to the previous fiscal year is the change in the biomass emission factor.

Trends in the Amount of Renewable Energy Generation*1*2

*1The amount of electricity generated by wood biomass power generation is only from Sumitomo Forestry's consolidated subsidiaries

*2The aggregation period for fiscal 2021 and onwards is from January to December of each year

Wood Biomass Power Generation Business

The Sumitomo Forestry Group operates wood biomass power generation facilities that are fueled by recycled chips primarily using leftover from construction as raw materials, wood not suitable as a building material, and thinning leftover in forests and other unused forest resource.

The CO2 emitted by burning wood does not contribute to CO2 in the atmosphere as part of the life cycle of the trees because the CO2 in the atmosphere is absorbed through photosynthesis as the trees grow (concept of carbon neutrality). Therefore, the Group has been engaged in wood biomass power generation as a type of business that contributes greatly to the advancement of forestry, such as the effective use of wood, mitigation of CO2 emission and furthermore, the maintenance of local forest environments.

In February 2011, the Sumitomo Forestry Group entered this sector by acquiring a 34% stake in the urban-oriented Kawasaki Biomass Power Plant (generation capacity: 33 MW), which primarily uses scrap construction wood as its main fuel. In December 2016, we started commercial operation of Mombetsu Biomass Electric Power (generating capacity of 50 MW), which is fueled mainly by unused wood from forests in Japan, followed by Tomakomai Biomass Power Generation Plant (generating capacity of 6.2 MW) in April 2017, Hachinohe Biomass Power Generation Plant (generating capacity of 12.4 MW) in April 2018, and Kanda Biomass Power Generation Plant (generating capacity of 75 MW) in June 2021.

Morinomiyako Biomass Power Generation Plant (generation capacity 75 MW), starting to operate in November 2023, bringing total power generation capacity of wood biomass power generation plant to approximately 251.6 MW, which means approximately electricity supply to 555,000 households. This plant is under management of the Sumitomo Forestry Group.

Drawing on past experience in the wood biomass power generation business, the Group will continue to expand renewable energy business operations suited to local conditions and other requirements.

Mombetsu Biomass Electric Power

Hachinohe Biomass Electric Power

Sumitomo Forestry Group's wood biomass power generation business

| Title | Location | Power generation capacity | Start of operations | Main features |

|---|---|---|---|---|

| Kawasaki Biomass Electric Power Co., Ltd. (Joint investment with Sumitomo Joint Electric Power Co., Ltd. and Fuluhashi EPO Corporation) |

Kanagawa Prefecture Kawasaki City |

33MW | February 2011 |

|

| Mombetsu Biomass Electric Power Co., Ltd.* (Joint investment with Sumitomo Joint Electric Power Co., Ltd.) |

Hokkaido Mombetsu City |

50MW | December 2016 |

|

| Tomakomai Biomass Power Co., Ltd. (Joint investment with Mitsui & Co., Ltd., Iwakura Corporation and Hokkaido Gas Co., Ltd.) |

Hokkaido Tomakomai City |

6.2MW | April 2017 |

|

| Hachinohe Biomass Electric Power Co., Ltd.* (Joint investment with Sumitomo Osaka Cement Co., Ltd. and East Japan Railway Company) |

Aomori Prefecture Hachinohe City |

12.4MW | April 2018 |

|

| Kanda Biomass Energy K.K. (A joint capital venture between RENOVA Inc., Kyuden Mirai Energy Co. Inc., and Mihara Group K.K.) |

Fukuoka Prefecture Miyako District |

75MW | June 2021 |

|

| Morinomiyako Biomass Energy G.K. (Joint venture with RENOVA Inc., United Corporation) |

Miyagi Prefecture Sendai City |

75MW | November 2023 |

|

*A consolidated subsidiary of Sumitomo Forestry

Solar Power Generation Business

Sumitomo Forestry owns a solar power generation facility that can generates 3.4 MW in Kashima City, Ibaraki Prefecture.

For some solar panel mounts, we have adopted original wooden mounts mainly made of domestically produced cedar wood to reduce the environmental load of power generation facilities and expand the use of wood.

In fiscal 2024, the combined output of power generation was 4,420,000kWh.

Solar panels and environmentally conscious wooden frames

Visualization in Investment

Sumitomo Forestry is considering the introduction of internal carbon pricing in order to use greenhouse gas emissions as one of the criteria when deciding whether or not to invest in a project.

Investment in Japan Green Investment Corp. for Carbon Neutrality

Sumitomo Forestry has invested in Japan Green Investment Corp. for Carbon Neutrality (JICN), which was established in October 2022 based on the Act on Promotion of Global Warming Countermeasures.

JICN develops fund business with capital from government fiscal investment and loans and private investment, and encourages private companies to invest in decarbonization by investing in and financing projects that contribute to decarbonization. The Sumitomo Forestry Group supports the purpose of JICN's activities and has invested in JICN because the Group believes that the growth of the decarbonization-related market will lead to expanded business opportunities. We will also accumulate information and knowledge on advanced cases in the decarbonization field supported by JICN in order to create future business opportunities for our Group.

- Home

- Sustainability

- Environment

- Responding to Climate Change

- Mitigation of Climate Change