- Home

- Sustainability

- Social

- Supply Chain Management

- Supply Chain Management in the Distribution and Manufacturing Businesses

Supply Chain Management in the Distribution and Manufacturing Businesses

- Basic Policy

- Structure of Wood Procurement Management

- Procurement of Sustainable Timber and Wood Products

- Use of Sustainable Wood

- Education for Personnel in Charge of Procurement

- Assessing Wood Procurement by onsite interviews

- Communication with Our Business Partners

- Responsible Material Procurement

Basic Policy

The Sumitomo Forestry Group strives to contribute to building a sustainable and prosperous society through business activities that use wood, a renewable natural resource. To do so, we engage in responsible wood procurement activities in accordance with our Wood Procurement Basic Policy formulated in 2005 and our Wood Procurement Principles and Policies formulated in 2007. To deliver legal and sustainable wood, we only engage in responsible wood procurement.

In 2015 with the Sumitomo Forestry Group Procurement Policy, we expanded our scope beyond timber to include a wide range of other procured products, such as metals, ceramics, resin and other building materials, and based on this policy, are engaged in procurement activities that take into consideration the economy, society and environment.

The Sumitomo Forestry Group's sustainable wood procurement initiatives have responded to growing concerns about deforestation as one of the climate change factors with the introduction of our own wood procurement due diligence. In May 2019, we newly implemented an Action Plan for the wood procurement due diligence that does not contribute to deforestation in order to further reinforce evaluation standards for sustainability.

Definition of Sustainable Timber and Wood Products

To confirm collateral of legal compliance as precondition, the Sumitomo Forestry Group defines timber and wood products as sustainable if they fulfill one of the following.

Definition of "sustainable timber and wood products"

- Environmental aspects: Not contributing to deforestation

- Social aspects: Not violating human rights such as occupational safety, forced labor, indigenous rights, etc.

Definition of "sustainable timber and wood products"

- Environmental aspects: Not contributing to deforestation

- Social aspects: Not violating human rights such as occupational safety, forced labor, indigenous rights, etc.

- Certified timber and materials sourced from certified forests: FSC, PEFC, and SGEC

(Regardless of CoC connection, we place emphasis on certification at time of production and promote a shift to certified timber) - Wood from planted forests

-

Wood from natural forests where forest management and distribution can be assessed as sustainable.

(this does not include wood from conversion forests = wood harvested from natural forests that were converted to farm land such as oil palm plantations) - Recycled wood

- Click here for related information

Structure of Wood Procurement Management

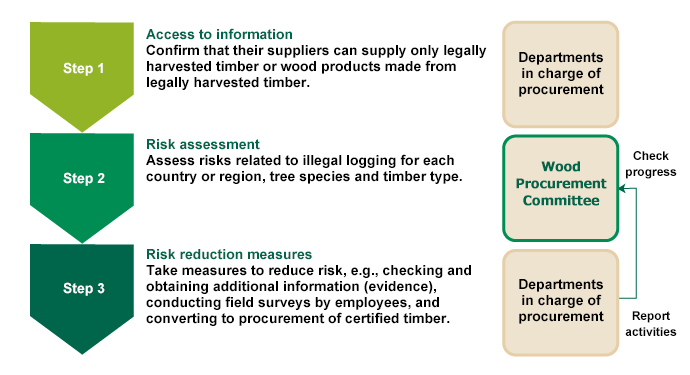

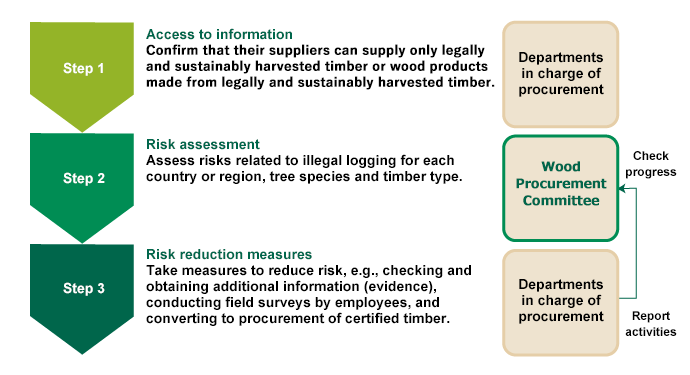

The Sumitomo Forestry Group established the Wood Procurement Committee, chaired by the officer in charge of sustainability promotion at Sumitomo Forestry and comprising managers from departments in charge of wood procurement. The committee discusses issues related to group-wide wood procurement, including procurement standards and risk assessments for illegal logging.

In fiscal 2024, the Wood Procurement Committee met four times to confirm the legality and conduct a "Sustainability Survey" for all 222 directly-imported suppliers and also suppliers engaged by overseas Group companies (distribution) that are subject to screening and to conduct a "Sustainability Procurement Survey." Regarding screenings, regardless of whether our suppliers are new or existing suppliers, we regularly (once a year or once every two years) confirm their legality and sustainability, based on country-specific risks.

Wood Procurement Committee meeting

Procurement of Sustainable Timber and Wood Products

Due Diligence in Wood Procurement

Timber and Building Materials Business, Housing Business and each of wood procurement division at each Group company confirm that the wood provided by suppliers has been legally harvested, or that the timber and wood products they provide have been made only from legally harvested wood as a raw material.

Confirmation of Legality of Wood Procurement

Each person in charge of procurement is required to follow the Wood Procurement Due Diligence Manual, gather the following information, cross-check relevant documents for each location and tree species, and confirm traceability of the entire supply chain all the way to the logging site. The Sustainability Procurement Survey consists of 52 items that are selected by referring to other surveys, such as forest certification, surveys from suppliers, and general sustainability surveys.

| No. | Category name |

|---|---|

| 1 | Supplier name |

| 2 | Supplier address |

| 3 | Wood type |

| 4 | Tree species of timber and wood products |

| 5 | Country or region of logging of timber and wood products |

| 6 | Annual procurement volume (weight, area, volume or quantity) |

| 7 | If sold to a legal entity, the name and address of that legal entity |

| 8 | Results of supplier surveys and other, inspection records and other |

| 9 | Documents certifying that harvesting was conducted in accordance with laws and regulations of the logging country |

Risk level

With this information sorted by country, region, tree species, and wood type, risk assessment on the illegal logging or human rights violation is carried out based on procurement standards stipulated by the Wood Procurement Committee. Risk categories are determined according to such information from Transparency International's CPI (Corruption Perception Index), FSC' national risk assessment, UNEP/WCMC (United Nation Environment Program/World Conservation Monitoring Center) and reports from environmental NGOs to be A (low risk), B (medium risk) and C (high risk). Even when suppliers are identified as A (low risk), they are all assessed regardless of the volume or duration of contracts, since our business is centered on wood and timber and wood products suppliers should not be considered as non-significant. Timber and wood products in the B (medium risk) and C (high risk) categories should not be solely evaluated with documentation to prove that they are legally harvested according to that country’s laws and regulations. In addition, when necessary, company staff are sent for on-site inspections to ensure traceability back to the logging site. In fiscal 2024, we audited 54 companies in Category A, 36 companies in Category B, and 132 companies in Category C.

Status of timber by region, and timber and wood products

(results for January to December 2024)

Ensuring Sustainability of Wood Procurement

Consideration for Biodiversity Conservation, Labor Practices and Human Rights, and Local Communities

We confirm the following items regarding timber and wood products we procure by conducting a Sustainability Procurement Survey of suppliers, on-site inspections, and interviews:

- Whether the rights of workers, local and indigenous communities are not abused in the area where we procure the products and their raw materials from. In addition, whether suppliers ensure their logging is conducted with consideration of the rights of workers and local residents.

- Whether the high conservation values forests are not included in the area where we procure the products and their raw materials from. In addition, whether suppliers ensure their logging practices are conducted with consideration for forests with high conservation value.

- Whether wood is not used if it comes from forests being converted into oil palm plantations or similar land uses.

Sustainability procurement survey implementation rate of suppliers of imported timber*

100%

* Number of suppliers conducting sustainability surveys as a percentage of the number of suppliers subject to wood procurement due diligence by the Wood Procurement Committee during the year under review.

Initiatives for Sustainable Wood Procurement

Sumitomo Forestry established an Action Plan to shift to alternative materials (from selective logging of natural forests and planted forests) and gradually stop handling wood products that do not meet the definition of "sustainable timber and wood products" even when their legality can be confirmed.

In September 2021, we suspended contracts with suppliers who did not meet our procurement standards and whose sustainability could not be confirmed through repeated dialogues. For example, we have stopped handling some raw materials harvested in Indonesia, Malaysia and Russia. As a result, we achieved 100% handling of sustainable timber and wood products on a contract basis. We will continue to thoroughly implement sustainable wood procurement.

Percentage of sustainable timber and wood products handled

FY2024 result*

100%

* "Sustainable timber and wood products" is defined as certified timber and timber in the process of certification, timber from forestation or from natural forests that are recognized as sustainable in terms of forestry and distribution (excluding timber from converted forests), and recycled timber.

Review of Legal Compliance and Sustainability by the Wood Procurement Committee

Each procurement department reports the progress of these initiatives to the Wood Procurement Committee, and transactions are permitted only with suppliers that are judged to have no issues regarding legality and sustainability. We will continue to pursue ongoing improvements aimed at reducing risks within our supply chain.

Due Diligence in Wood Procurement

Use of Sustainable Wood

Manufacturing Business Initiatives

Sinar Rimba Pasifik (SRP) uses sustainable wood that takes into consideration the environment and at the same time, manufactures high-quality wood interior materials (floors, stairs, counters, etc.) of a consistent design and supplies products primarily for Sumitomo Forestry homes. SRP procures only sustainable wood as the main raw material for these products, and is also promoting the use of plantation wood.

Approximately 70% of wood used was imported from North America, all of which is certified wood from member companies of the American Hardwood Export Council (AHEC) or Quebec Wood Export Bureau (QWEB), which promote sustainable forest management.

The remaining wood procured is plantation wood from Indonesia (Perum Perhutani), all of which are materials that have received SVLK (Sistem Verificasi Legalitas Kayu) certification.

We will continue to pursue sustainable wood and manufacture and sell high-value-added products that use verified as legal and sustainable wood.

Wood Storage Warehouse

Promotion for Sales of KIKORIN-PLYWOOD

Among these products, JAS Plywood that uses 50% or more FSC-certified or PEFC- certified timber and sustainable planted forest wood is marketed as "KIKORIN- PLYWOOD," and some of its revenue is invested in forestry business implemented in Indonesia. Since fiscal 2021, the definition of "KIKORIN-PLYWOOD" has aligned with Sumitomo Forestry Group's Wood Procurement Standards as "plywood using 100% of sustainable certified timber," and we will strive to further expand sales. Sales performance in fiscal 2024 under new definition are 309,024m3.

KIKORIN-PLYWOOD

Education for Personnel in Charge of Procurement

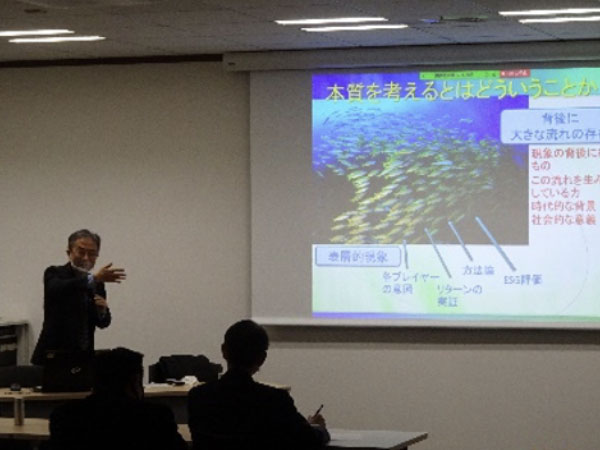

In order to deepen the understanding of those in charge of wood procurement, the Sumitomo Forestry Group holds study session- once a year with external experts in the Wood Procurement Committee to learn about current trends and the latest information in the world.

Sustainability in Wood

In December 2024, the Sumitomo Forestry Group, with the cooperation of the Wood Utilization Division of the Forestry Agency, held a study session titled "Sustainability in Wood."

During the study session, participants learned about the revised Clean Wood Act, which came into effect on April 1, 2025, the sustainability of wooden biomass fuel, evaluation guidelines for wood use in buildings, and forestry management guidelines to enhance forest biodiversity. We also discussed the initiatives that companies will be expected to undertake in the future.

Wood Utilization Division, Forestry Agency, Forestry Department

Study Session by Auditor Ms. Aya Saito

Study Meetings Held to Date

| Theme | Description | Lecturer | |

|---|---|---|---|

| FY2020 | Recent trends and the nature of ESG investment | The major trends behind "why ESG investment?" | Professor, Takasaki City University of Economics

Professor Takeshi Mizuguchi |

| FY2021 | Sustainable wood procurement from a financial perspective | Main outcomes of COP26, forests in ESG investment and financing policies of financial institutions, forest certification from a financial perspective, TNFD, etc. | WWF Japan Head of Financial Group Mutai Hashimoto |

| FY2022 | Supply Chain and Human Rights | Covered the background of the issue of business and human rights, international codes of conduct, tightening international standards, and domestic and international trends such as legislation on human rights and due diligence in various countries. | LRQA Sustainability K.K.

Representative Director Hidemi Tomita |

| FY2023 | Biodiversity, Nature Positive, and Timber Procurement | The current state of biodiversity, global trends, and international trends that are shifting from climate change to nature. |

WWF Japan

General Manager of the Nature Conservation Department Mr. Shinichi Kawae |

Assessing Wood Procurement by onsite interviews

Wood Procurement in Romania

Several environmental groups have expressed concerns about forest management and wood production in Romania in terms of whether logging has been appropriately conducted. In April 2017, members of the Wood Procurement Committee conducted on-site inspections, first gathering information through meetings with such organizations as the Ministry of Environment and Forests of the Romanian Government, the Embassy of Japan in Romania, ASFOR (Romanian Forest Association), among others. The members also went to a supplier manufacturing facility and inspected representative logging sites of logs that were transported to the facility. At the manufacturing facility, they confirmed that the supplier properly checks transport permits and the logs bundled on the trailer when receiving raw material logs at the timber manufacturing plants. For example, the visiting team was able to confirm that the supplier was thorough in segregated management to ensure that logs exceeding the amount permitted were not used and that they engaged in such measures as reporting to forestry authorities. The team received an explanation about forest management from a forest ranger at the logging site and checked the actual hammer stamp mark and process when loading the trailer in the field. In addition, they were able to confirm the dedication to preserving the rare forest ecosystem by observing forest conservation areas under the Romanian government's jurisdiction.

Inspection of harvest land still covered in snow

Check when loading the trailer

Properly checking the delivery at the plant using tablet terminals

Segregated management of round wood beyond the amount on the permit

Concrete Form Plywood from Indonesia

In recent years, several environmental groups have expressed their concerns about the legality of the logs used as raw material for plywood manufactured in Indonesia. In Indonesia, the SVLK timber legality verification system is in place, requiring timber product manufacturers and exporters to register by obtaining SVLK business certification issued by an independent evaluation and certification organization recognized by the National Accreditation Committee. Upon doing so, the business obtains documentation (V-Legal documents) from the independent verification and certification body certifying the wood as legal, and expressly confirming the legality of the entire supply chain, from logging to wood processing at manufacturing plants to export. In July 2018, we conducted an on-site inspection of the concrete formwork paneling plywood manufacturing plant that serves as our supplier. At a wood yard near the harvesting site, we were able to use QR-code labeling on tags attached to logs to confirm the harvesting information at the Indonesian Ministry of the Environment and Forestry website, as well as with V-Legal documentation. After the same logs were transported to the plant, we were once again able to use QR codes at a plant wood yard to access the ministry website and V-Legal documents, successfully tracing them back through the transport process to their harvest location.

Confirming tags attached to the logs at the plant wood yard

Confirming tags at an intermediate wood yard

Confirming the harvest site from tag information at the logging company (1)

Confirming the harvest site from tag information at the logging company (2)

In relation to plywood for concrete formwork used in the construction of Olympic-related facilities, in November 2018, an environmental NGO submitted an allegation to the Reporting Desk established by the Organizing Committee for the Olympic Games that logs used as raw materials by suppliers who have business relationships with Sumitomo Forestry may not conform to the Olympic procurement standards. Sumitomo Forestry responded to the report by presenting relevant documents and explaining to the Organizing Committee that such logs were not included in the supply chain. As a result, the Organizing Committee concluded that the allegations were untrue, and the report was not accepted, and was published on the website of the convention in February 2019.

In November 2021, a similar point was brought to the Tokyo Metropolitan Government's Olympic and Paralympic Preparation Office, which built related facilities. Sumitomo Forestry reiterated to the Tokyo Metropolitan Government that it complies with the Olympic procurement standards.

Plywood from Sarawak, Malaysia

In recent years, as is the case with Indonesia, several environmental groups have expressed their concerns about the legality of the logs used as raw material for plywood manufactured in Sarawak, Malaysia. Sarawak Forestry Corporation was established in 2003 for the purpose of eliminating illegal logging in Sarawak, Indonesia. Thereafter, the Sarawak Timber Legality Verification System (STLVS) was created in 2015 to further strengthen efforts to eliminate illegal logging, reflecting the trend of elimination of illegally logged timber in countries such as the United States, the EU, and Australia. Sumitomo Forestry conducted an on-site audit of a plywood production plant of one of its suppliers in September 2019 to primarily confirm whether the STLVS was properly in operation from the logging sites to the plant landing.

We were able to confirm that tracking is possible from logs arriving at the plant to the harvesting district via identification processes such as orange tags proving royalty payments (for processing domestically), white tags (for log production) as well as markings and relevant transfer permits from regional forest offices through the detailed logging plans and tree logging lists required by STLVS. In addition, a signature from a representative in charge of the regional forest office on the back of the export application (K2) necessary to export plywood products confirms the products satisfy all of the STLVS standards.

Logs for Plywood Stacked at a Log Pond

Log Production Tag (White) and Royalty Tag (Orange) at the Log Pond

Logs Stacked at the Landing of the Plywood Production Plant

Confirming the Royalty Number Written on the Log Delivery Ledger

Communication with Our Business Partners

In the Timber and Building Materials, given that it is characterized as being a regional industry, Sumitomo Forestry maintains close communication with the suppliers and purchasers of timber and building materials in each region.

Main Communication Activities with the Business Partners of the Timber and Building Materials Division

| Name/Scale | Description |

|---|---|

| The Sumirin club

-a membership organization to communicate with regional suppliers of timber and building materials Number of members: 889 companies (as of July 2024) |

Established in different regions around Japan as a forum for communication with business partners for distribution operations of timber and building materials. Training sessions and informational exchange meetings are held two or three times a year in each region, allowing members to deepen mutual friendships, promote product R&D, enhance production and distribution, and support improvements in the industry as a whole. |

| Publication of Building Materials Monthly Monthly print run of approximately 4,100 copies |

With a history spanning more than half a century, this monthly magazine publishes timely information and topics regarding timber, building materials and the housing industry from our distinct perspective. |

Dennagon (Digital Delivery Slip and Invoice Transmission Service)

The Timber and Building Materials Division launched the Dennagon service in October 2016 as a website to access and receive digital versions of delivery slips and invoices traditionally exchanged on paper.

Using the Dennagon service provides the benefits below.

- Purchasers can now receive the delivery slips and invoices the morning after they are issued by the Company instead of waiting for them to be delivered at an unknown time several times a week. The service also streamlines the tasks to process delivery slips based on the purchasers.

- The work to check the content of delivery slips is made more efficient as well through a sorting function of the delivery data in Excel, with which the purchasers can easily find desired data.

- The Dennagon service stores delivery slips for ten years and eliminates filing tasks by allowing various searches to help increase efficiency while reducing costs of operations at purchasers.

Another benefit of the service during the coronavirus disease (COVID-19) was the ability for purchasers to verify our delivery data without being in the office. As of fiscal 2024, roughly 950 of our business partners are using this service.

Responsible Material Procurement

Since fiscal 2022, the Sumitomo Forestry Group has been conducting the Sustainability Procurement Survey for its suppliers of building materials and housing equipment in its domestic timber and building materials business.

The main purposes of conducting the survey are (1) to ensure that the goods and services provided by the Sumitomo Forestry Group comply with various environmental and social laws and regulations throughout the supply chain, and (2) to share the Sumitomo Forestry Group's Procurement Policy, Human Rights Policy, etc. and to build better partnerships.

Conventional supply chain management refer to quality, cost and delivery, but in addition to these items, risks related to workers' rights, occupational safety and environmental issues must also be recognized and managed.

The content of the Sustainability Procurement Surveys questionnaire is based on international norms and the Sumitomo Forestry Group policies and consists of questionnaires on governance, human rights, occupational health and safety, the environment, ethics, information security, supply chain and social contribution.

In fiscal 2024, questionnaires were sent to 78 companies, and all 78 responded. The collection rate was 87.0% of sales, exceeding last year's 83.5%.

Implementation of web-based questionnaires

- Home

- Sustainability

- Social

- Supply Chain Management

- Supply Chain Management in the Distribution and Manufacturing Businesses