- Home

- Sustainability Report

- Environment

- Resource Conservation and Waste Reductions

- Initiatives to Achieve Zero Emissions

Resource Conservation and Waste Reductions

Initiatives to Achieve Zero Emissions

The Basic Concept of Zero Emissions

The Sumitomo Forestry Group defines achievement of zero emissions as a recycling rate of 98% or more using no simple incineration or landfill for all industrial waste produced by each business site*. Based on this definition, domestic manufacturing facilities achieved zero emissions in fiscal 2009 while new housing construction sites achieved zero emissions in metropolitan areas in fiscal 2012. Our overseas manufacturing plants achieved zero emissions in fiscal 2020.

Mid-Term Sustainability Targets from fiscal 2019 to fiscal 2021 set a target of 15% reduction in the amount of final disposal throughout the entire Sumitomo Forestry Group compared to fiscal 2017 to promote further reduction of environmental impact in our business activities. As a result, the final disposal amount was reduced by 66.9%. In addition, we aimed to achieve zero emissions through more detailed management than the conventional medium-term plan by dividing them into seven categories of new construction sites, domestic manufacturing plants, power generation business, remodeling and renovation business, lifestyle service business, etc., overseas manufacturing plants, and demolition work site in consideration of status of business activities and waste generated. As a result, we achieved zero emissions at our power generation plants in addition to our domestic and overseas manufacturing plants.

In the Mid-Term Sustainability Targets, which newly set the target year from fiscal 2022 to fiscal 2024, we will continue to set targets such as for the final disposal volume of industrial waste and the recycling rate, and to reduce our environmental impact.

* Includes new housing construction sites, domestic manufacturing plants, power generation plants, remodeling and renovation businesses, lifestyle service businesses, etc., overseas manufacturing plants, and demolition work sites

Manufacturing Business Initiatives

Initiatives at Domestic Manufacturing Facilities

Sumitomo Forestry Group managed to achieve a recycling rate of 99.1% against the target of 99.5% while zero emissions (recycling rate of 98% or more) were achieved at Agro-Products division of Sumitomo Forestry Landscaping and Sumitomo Forestry Crest in fiscal 2021* as a result of ongoing efforts to reduce waste emissions, for example by tightening the sorting of industrial waste at each manufacturing plant, effective use as resources (thermal use) without simple incineration, and selling it for a profit.

Initiatives at Overseas Manufacturing Plants

We are working toward zero emissions with two new Group companies from fiscal 2019: Sinar Rimba Pasifik (SRP) in Indonesia and Canyon Creek Cabinet (CCC) in the United States in addition to five main manufacturing companies outside Japan*. For example, Kutai Timber Indonesia is advancing zero emissions activities from the collection of wood waste generated during the particle board manufacturing process to reuse as boiler fuel or in wood building materials as well as the use of offcuts produced in manufacturing products as novelty goods.

The recycling rate in fiscal 2021 achieved zero emissions at 98.5% against our target of 98.0%.

* Indonesia: PT. Kutai Timber Indonesia, PT. Rimba Partikel Indonesia, and PT. AST Indonesia

New Zealand: Nelson Pine Industries Ltd.

Vietnam: Vina Eco Board Co., Ltd.

Recycling by sorting waste

Recycling by sorting waste manufacturing as raw materials for novelty goods

Housing and Construction Business Initiatives

Efforts at New Housing Construction Sites

Initiative for Reduction of Industrial Waste Generated at New Housing Construction Sites

Reduction Rate of Industrial Waste Generated at New Housing Construction Sites

From 2014, Sumitomo Forestry has launched a "waste reduction working" by personnel in charge of product development, material procurement, production control, and environment department, and has devised and implemented many measures to reduce waste at new construction sites.

We discovered two-thirds of all our waste is made up of wood waste, gypsum board and cardboard from detailed data about the waste that is produced aggregated from the industrial waste management system used under this inter-region certification, which has been in operation since 2012. We are working to reduce waste by concentrating on these three primary forms of waste.

Sumitomo Forestry Group Mid-Term Sustainability Targets has set a goal of reducing the amount of industrial waste generated from new construction sites by 18% per building until fiscal 2021 compared to fiscal 2017. Although emission of industrial waste per new-constructed building was stagnated at a 10% reduction in fiscal 2020, compared to fiscal 2017, pre-cutting of scratch panels and roof slate, which have started operation, has progressed smoothly, and a great effect has begun to appear in reducing industrial waste emissions.

This initiative has been operating at all offices and branches throughout Japan since fiscal 2021. With respect to roof slate material, it is expected to reduce 170 kg per building. We have also started to pre-cut siding in some areas and are gradually expanding this to others. Since the weight of waste from siding is 550 kg per building, we expect to further reduce industrial waste emissions through expanded operation in the future.

Due to differences in the amount of industrial waste emissions originating from factors such as the location, region and specifications of each construction site in fiscal 2021, we calculated the appropriate amount of industrial waste emissions and created the targets of appropriate amount of industrial waste emission for each branch. By setting proper industrial waste emission targets, Sumitomo Forestry will work to reduce waste emissions by renewing the thinking on construction sites, engaging in awareness-raising initiatives and analyzing the amount of industrial waste emissions while also planning and executing improvement plans.

Reduction Rate of Industrial Waste Generated at New Housing Construction Sites (Per Household)

| Total Emissions (kg) | Reduction Rate | |

|---|---|---|

| FY2017 (Baseline) |

3,325 | - |

| FY2019 result | 3,002 | -10% |

| FY2021 result | 2,977 | -10% |

| FY2021 result | 2,736 | -18% |

Initiative for Recycling of Industrial Waste Generated at New Housing Construction Sites

Sumitomo Forestry meticulously sorts waste produced on new housing construction sites. We will raise awareness through mediums such as posters including specific waste information to make sorting of the 11 categories of waste easier. We have also engaged in efforts to reuse rather than dispose of wood base and packing materials used when transporting precut structural and other materials.

Because of effects of soaring processing costs and labor shortages due to the spread of coronavirus disease(COVID-19), the recycling rate at the treatment facilities declined in fiscal 2021, resulting in a stagnation of 95.1% against the recycling rate target of 98%.

The Sumitomo Forestry Group set a goal of achieving 98.0% waste recycling rate for new construction sites by fiscal 2021 as part of the Mid-Term Sustainability Targets.

In fiscal 2022, we will work to increase the recycling rate by newly adopting treatment plants where recycling is possible, and expanding the promotion of manufacturer collection routes.

Waste Recycling Rate at New Housing Construction Sites

| Recycling Rate | |

|---|---|

| FY2017 (Baseline) |

92.5% |

| FY2019 result | 94.3% |

| FY2020 result | 95.2% |

| FY2021 target | 95.1% |

Posters About Sorting Industrial Waste

Acquisition of the Inter-Region Recovery and Recycling Certification by the Ministry of Environment

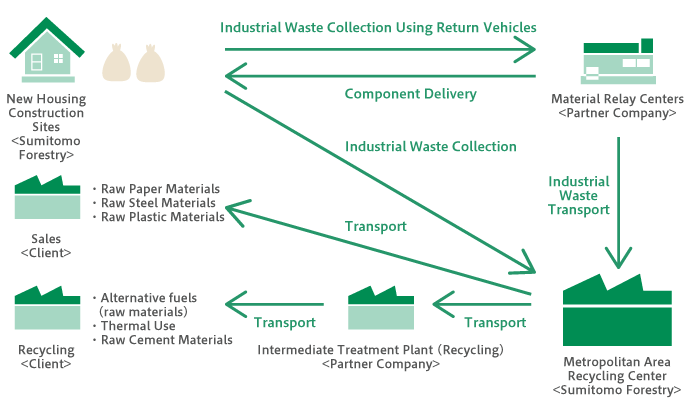

Sumitomo Forestry has been certified by the Ministry of the Environment under Inter-Region Recovery and Recycling Certification. This certification makes it possible for non-industrial waste companies to transport industrial waste, and we have built our own industrial waste recycling system.

Our industrial waste management system for new housing construction sites helps contribute to the rationalization of waste disposal by using returning transportation for collecting waste while also securing traceability by applying bar codes to waste and collecting accurate data about the volume of waste generated.

Operations at the Metropolitan Area Recycling Center

Sumitomo Forestry has used the acquisition of the inter-region recovery and recycling certification to establish the Metropolitan Area Recycling Center in Kazo, Saitama Prefecture for advanced sorting and data collection.

The Metropolitan Area Resource Recovery Center collects detailed data regarding waste generation conditions and trends by specification, construction contractor, and region, and utilizes the data in product development, material procurement, and production management departments for use in waste reduction initiatives.

The Metropolitan Area Resource Recovery Center collects detailed waste generation status and trend data for each specification, construction shop, and region, and uses the data for product development, material procurement, feedback to production management departments, and waste reduction efforts.

This initiative works to expand operation under the certification even in regions outside the metropolitan area. Currently, the system is in operation at branches except for in Kagoshima Prefecture and the Sanin area. In the same way data is collected by the Metropolitan Area Recycling Center, we can also gather data on the level of waste produced throughout Japan. The analysis of this data helps us reduce waste because we can discover trends in the amount and type of waste according to building specifications and construction conditions in each region.

Metropolitan Area Recycling Center

Flow of Industrial Waste Collection Using the Inter-Region Recovery and Recycling Certification

Efforts at Demolition Housing Sites

Sumitomo Forestry was promoting resource recycling even before the enactment of the Construction Material Recycling Law implemented in 2002 by ensuring that materials were properly sorted during demolition prior to the construction of a new house and that waste remained sorted for processing afterwards. Since the enactment in 2002, the Company has recycled the items required under the Law (wood waste, concrete, etc.), sorting them at the sites where the waste is generated. In recent years, demolition work of housing built using construction materials containing asbestos has increased, and revised law related to asbestos were also enacted in 2020. Sumitomo Forestry especially strives for uncompromising compliance to removal method, processing guidance and management of construction materials containing asbestos.

Waste Management for Demolition Work

We are strengthening management by building a system able to confirm the type, quantity and packaging of waste to transport from demolition work sites using mobile phones and smartphones which is adopted by our demolition partners.

Launch of Industrial Waste Management Centers

Sumitomo Forestry opened three industrial waste management centers throughout Japan in fiscal 2021. Managers specializing in industrial waste management make every effort to eliminate industrial risks throughout Japan by consolidating highly accurate management processes.

These management processes include precise process confirmations and deadline management from electronic manifest registration of industrial waste produced throughout Japan through the final disposal obligations of the entity producing the emissions. These management practices strictly adhere to laws and regulations, such as checking information registered in the electronic manifest against the outsourcing contract and updates to outsourcing contracts.

Remodeling and Renovation Business Initiatives

We are working to reduce waste generated on remodeling and renovation sites by using reusable protective materials.

Our Group also strives to effectively use resources, such as the initiative to operate a material recycling route to reclaim wood waste from metropolitan areas as raw materials for particle board that started in fiscal 2014.

In the three major metropolitan areas with the most emissions, we have established construction departments to supervise the entire area and provide guidance and education on overall industrial waste management and ways to improve their recycling rate.

The recycling rate in fiscal 2021 was 79.7% due to the start of new deliveries of glass and ceramic waste to processing contractors with high-level recycling capabilities.

Work with Construction Contractors

Sumitomo Forestry publishes monthly safety, environment and quality inspection information that includes information and topics about safety and the environment to help avoid industrial waste-related risks by repeatedly raising awareness at branches and construction contractors.

Education for New Construction and Demolition Contractors

Sumitomo Forestry provides education to new construction contractors and conducts comprehension tests about industrial waste. Demolition contractors report about industrial waste to each office and branch from the start of demolition work to its completion as a construction management record according to a manual. Each office and branch verifies these construction management records and provides guidance for corrective actions if any inconsistencies are found.

Biomass Power Generation Business Initiatives

Maintenance of Forest Roads, etc. Using Rovander Foundation Filler Made with Incineration Ash

At Mombetsu Biomass Electric Power Co., Ltd., incinerator ash emitted by the biomass boiler is used to manufacture foundation fill material (product name "Rovander") for forest roads. This environmentally-conscious product is aimed at building a cyclical operation in which the amount of waste is controlled, reducing environmental impact by helping maintain forests using a by-product of power generated with timber resources.

In addition, Rovander has been recognized as meeting environmental safety standards, and is a Hokkaido Government-certified Recycled Product.

Road Laid with Rovander Wood from Log Storage

The Hokkaido Government-certified Recycled Product mark

Japan Bio Energy Co., Ltd. Recognized as Superior Industrial Waste Disposal Operator

Japan Bio Energy Co., Ltd., which manufactures and sells wood biomass chips, has been recognized as a superior industrial waste disposal operator in May 2016 by Kawasaki City.

The system to recognize superior industrial waste disposal operators evaluates and certifies superior industrial waste disposal operators through the prefecture or city. In order to receive this recognition, the business must satisfy a full set of criteria including legal compliance, business transparency, efforts in environmental conscious, and a healthy financial strength. The validity of certification in industrial waste disposal is extended from five to seven years by receiving recognition through this system.

In addition, it was awarded as an excellent business establishment by Resource Circulation Kanagawa in fiscal 2020. Excellent business establishments are selected by recommendation from each area, but it was recognized for solid business activities for more than five years.

- Home

- Sustainability Report

- Environment

- Resource Conservation and Waste Reductions

- Initiatives to Achieve Zero Emissions