- Home

- Sustainability

- Environment

- Resource Recycling Initiatives

- Waste Reduction and Recycling in the Manufacturing Business

Waste Reduction and Recycling in the Manufacturing Business

Initiatives at Domestic Manufacturing Facilities

The Sumitomo Forestry Group is making ongoing efforts to reduce waste emissions, for example by tightening the sorting of industrial waste at each manufacturing plant, promoting its effective use as resources without simple incineration (thermal use), and selling it for a profit.

The Sumitomo Forestry Group is making ongoing efforts to reduce waste emissions, for example by tightening the sorting of industrial waste at each manufacturing plant, promoting its effective use as resources without simple incineration (thermal use), and selling it for a profit. Wood waste generated during the production process is incinerated using biomass boilers or furnaces within our own factories. The heat generated is then utilized for drying equipment and air conditioning, contributing to a reduction in fuel consumption.

The Sumitomo Forestry Group managed to achieve a recycling rate of 99.1% against the target of 99.0% in fiscal 2024. Zero emissions (recycling rate of 98% or more) were achieved at offices of Sumitomo Forestry Crest, Sumitomo Forestry Landscaping and Agro-Products division.

Recycling Rate at Domestic Manufacturing Plants*

| FY2021 | FY2022 | FY2023 | FY2024 |

|---|---|---|---|

| 99.1% | 99.4% | 99.6% | 99.1% |

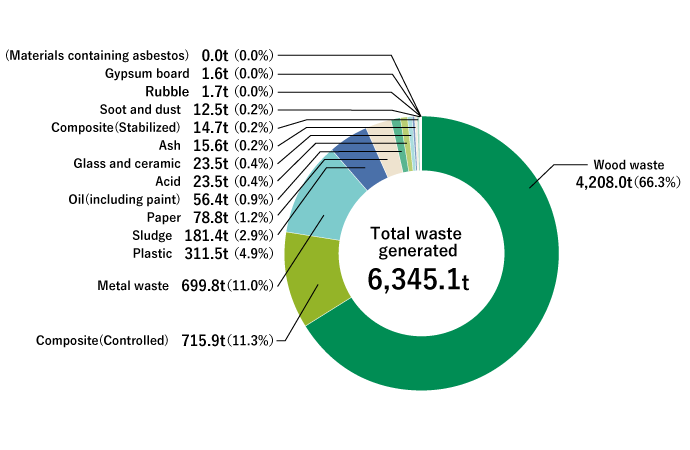

Breakdown of Waste Generated at Domestic Manufacturing Plants (FY2024)

*Sumitomo Forestry Crest, the Agro-Products division of Sumitomo Forestry Landscaping, Japan Bio Energy, Okhotsk Bio Energy, Michinoku Bio Energy

Initiatives at Overseas Manufacturing Plants

Seven major overseas manufacturing plants* are promoting zero emissions. Offcuts generated at plywood and building materials mills is reused as raw material for wooden board mills, and at wooden board mills, waste wood from the manufacturing process is reused as fuel for heat sources in the drying and thermal pressing processes. We also promote zero-emission activities by making effective use of all types of wood waste, such as using the offcuts generated at our wooden mills for novelty goods.

In fiscal 2024, the recycling rate improved to 98.4% as a result of promoting the reuse of wood waste at KTI, up from 95.7% in fiscal 2023.

We will continue our efforts to reduce waste, including the effective utilization of wood waste.

*Indonesia: PT. Kutai Timber Indonesia, PT. AST Indonesia, PT. Sinar Rimba Pacifik

New Zealand: Nelson Pine Industries Ltd.

Vietnam: Vina Eco Board Co., Ltd.

United States: Canyon Creek Cabinet Company

Thailand: Pan Asia Packing Ltd.

Recycling by sorting waste

Recycling by sorting waste manufacturing as raw materials for novelty goods

Recycling Rate at Overseas Manufacturing Plants

| FY2021 | FY2022 | FY2023 | FY2024 |

|---|---|---|---|

| 98.5% | 98.0% | 95.7% | 98.4% |

Breakdown of Waste Generated at Overseas Manufacturing Plants (FY2024)

*Sumitomo Forestry Crest, the Agro-Products division of Sumitomo Forestry Landscaping, Japan Bio Energy, Okhotsk Bio Energy, Michinoku Bio Energy

Japan Bio Energy Recognized as Superior Industrial Waste Disposal Operator

Japan Bio Energy, which manufactures and sells wood biomass chips, has been recognized as a superior industrial waste disposal operator since 2016 by Kawasaki City.

The system to recognize superior industrial waste disposal operators evaluates and certifies superior industrial waste disposal operators through the prefecture or city. In order to receive this recognition, the business must satisfy a full set of criteria including legal compliance, business transparency, efforts in environmental conscious, and a healthy financial strength. The validity of certification in industrial waste disposal is extended from five to seven years by receiving recognition through this system. In addition, current waste disposal business license and certification as a superior industrial waste disposal operator were renewed in May 2023.

- Home

- Sustainability

- Environment

- Resource Recycling Initiatives

- Waste Reduction and Recycling in the Manufacturing Business