- Home

- Sustainability

- Social

- Occupational Health and Safety

- Occupational Health and Safety Management

Occupational Health and Safety Management

Basic Policy

The Sumitomo Forestry Group has established the Sumitomo Forestry Group Occupational Health and Safety Policy in order to further improve occupational health and safety activities in its corporations. Based on the fundamental concept of "SAFETY FIRST" and the implementation of the policy, we seek to create a thriving workplace by maintaining a healthy and safe work environment.

Sumitomo Forestry and all Sumitomo Forestry Group companies, as well as business partners involved in the Group's operations, are required to routinely engage in occupational health and safety activities as the foundation of corporate management in line with this policy.

The policy reflects the expectations of stakeholders for quality improvement, which were gathered through a questionnaire survey of Group employees on their quality values and activities, as well as interviews with internal executives, senior managers, and major business partners.

In addition to disclosing this policy on our website, we also use various tools to promote understanding and penetration of the policy, such as posting it on posters and including it in the employee handbook.

In addition, Sumitomo Forestry has established Rules for Safety and Health Management with an aim of fostering a workplace environment in which employees can perform their jobs in a safe and healthy manner. The rules prescribe that a general OHS manager is to be stationed at each place of business regardless of its size, and adherence to such rules along with status of OHS committee meetings are checked annually.

Sumitomo Forestry Group Occupational Health and Safety Policy

Based on the fundamental concept of "SAFETY FIRST", the Sumitomo Forestry Group seeks to create a thriving workplace by maintaining a healthy and safe work environment.

- Full employee participation in health and safety initiatives

All employees of our Group's operations shall consciously participate in health and safety initiatives. - Thorough compliance

We shall strictly comply with all laws, ordinances, safety standards and other rules related to occupational health and safety. - Reducing risk and creating a thriving workplace

We shall identify hidden risks in the work environment and continuously make improvements to create a thriving workplace. - Securing safety with state-of-the-art technologies and labor-saving measures

We shall create a safe workplace by actively promoting the use of state-of-the-art technologies and labor-saving measures that will help address personnel shortages and technical transfer issues. - Nurturing a culture of mutual respect

We shall nurture a culture where everyone respects both the processes and the results of health and safety initiatives to increase motivation to pursue them. - Developing human resources through health and safety training programs

We shall provide all employees health and safety training and we shall actively pursue initiatives to develop human resources who will take on the responsibility of creating a thriving workplace. - Promoting active communication

Through the active pursuit of mutual dialogue, including with stakeholders, we shall build good relationships that help ensure a sense of psychological security.

President and Representative Director

Toshiro Mitsuyoshi

Occupational Health and Safety Management System

Promotion System

The Sumitomo Forestry Group has established Quality Control and Worker Safety Management Department as an office directly under the president with a mission to consistently improve product and service quality and eradicate occupational accidents. The office provides guidance and advice to the entire Group in Japan and overseas, as well as developing and strengthening the quality and occupational health and safety management system. In addition, the Sustainability Committee considers and reports on important occupational health and safety issues that affect the entire Group. We conducted a survey of the current status of safety management systems at 73 Group divisions in Japan and overseas in fiscal 2024 and presented the findings at the Sustainability Committee and other entities.

Personnel department manages non-consolidated OHS of the Sumitomo Forestry, and the General Manager of the personnel department provides OHS instructions and supports offices in establishing OHS systems. In addition, OHS committees chaired by the General Managers of each offices and composed of members such as health and safety managers, industrial physicians, and labor union members are established at each office, and matters discussed each month are posted on the intranet for the purpose of information sharing and enlightenment.

We have established individual policies and manuals for safety and health management in each of our businesses, such as Forestry, Manufacturing, Environment and Energy, and Housing, based on the characteristics of each business, aiming to prevent accidents at work sites and ensure workers' health.

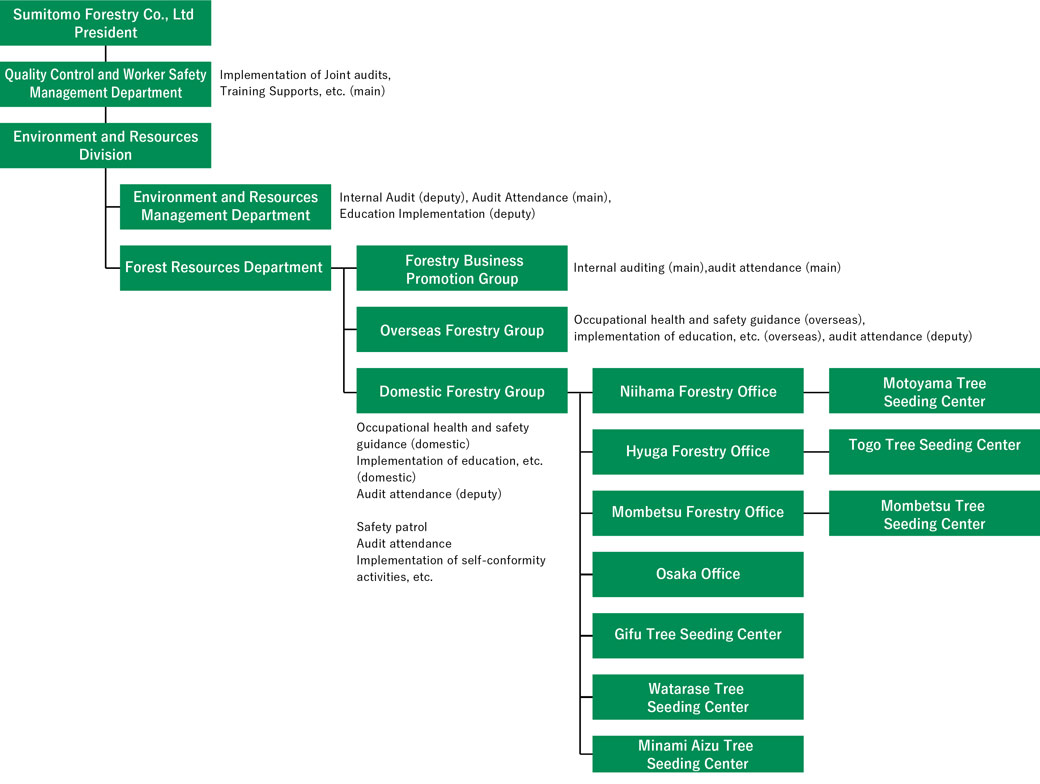

Occupational Health and Safety Management System in Forestry Business

Forest Resources Department is promoting establishment of an Occupational Health and Safety Management System (ISO 45001) and acquiring ISO 45001 certification step by step to ensure a safe working environment. In fiscal 2024, Mombetsu Forest Office and Mombetsu Tree Nursery Center obtained certification. In January 2025, the Osaka Forestry Office made a self-declaration of conformity*. In each office, a safety conference and safety patrol are periodically held to eradicate occupational injury.

*A declaration by the company that it has established, operated and adapted an ISO-based management system

Occupational Health and Safety Management System Chart of Forest Department

Occupational Health and Safety System for Environmental Energy Business

The company is responsible for comprehensive management of health and safety of consolidated subsidiaries such as Mombetsu Biomass Electric Power, Hachinohe Biomass Electric Power, Okhotsk Bio Energy, Michinoku Bio Energy, and Japan Bio Energy, as well as equity method associated Kawasaki Biomass Electric Power, Tomakomai Biomass Power, Kanda Biomass Energy, and Morinomiyako Biomass Energy. The Group also performs quarterly disaster drills, frequent inspections of firefighting equipment, and safety training to confirm progress, in addition to reporting occurrence of occupational injuries and sharing information how to prevent recurrence at monthly meetings.

Occupational Health and Safety Management System in Domestic Manufacturing Business

Sumitomo Forestry Crest Co., Ltd. has acquired ISO 45001 certification in its operation of Occupational Health and Safety Management System (ISO 45001). The ISO 45001 promotion staff at each plant leads the efforts to meet targets and track progress. To ensure workplace safety, the Safety & Environment Department, which serves as the secretariat, coordinates activities of each facility and communicates health and safety information with the Sumitomo Forestry Group overseas manufacturing enterprises.

Each plant appoints a general health and safety manager in compliance with the Occupational Health and Safety Law as part of our health and safety management system, and a Health and Safety Committee meeting is held once a month with these members playing a prominent role. Past workplace accident cases, near-miss reports, and traffic safety training are discussed in the Safety and Health Committee meetings.

Occupational Health and Safety Management System in Overseas Manufacturing Business

Safety and health officers are assigned to both domestic and overseas manufacturing companies, and Safety and Health Committee meetings are held every month to report on work-related accidents that have occurred, formulate countermeasures, analyze causes and formulate countermeasures for unsafe behaviors reported by safety patrols and Hiyari-Hatto (near miss), as well as check the status of various safety improvement activities, risk prediction training (KYT), and risk assessment activities.

Sumitomo Forestry's Head Office Departments also conduct periodic safety audits to review the safety and health management systems and activities of each manufacturing company. Since fiscal 2022, a remote safety audit system has been introduced using standardized audit checklists and locally recorded video footage, enabling more frequent audits.

Furthermore, when a work-related accident occurs at any factory, the case is immediately shared with all factories to raise awareness and help prevent similar incidents.

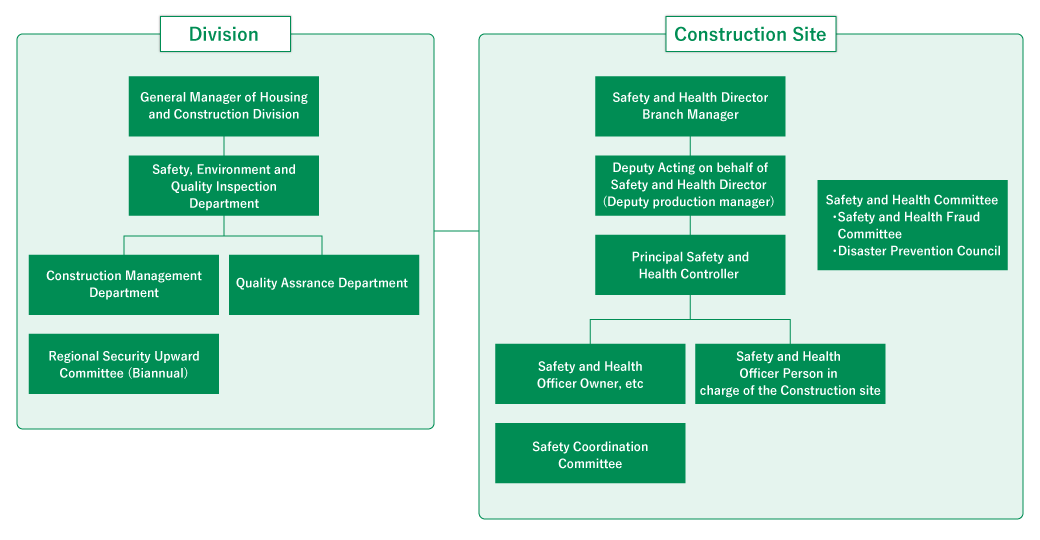

Occupational Health and Safety Management System in Housing Business

In accordance with Industrial Safety and Health Law, Housing Division has established a safety and health management system for building sites by designating branch and General Manager as Overall Safety and Health Manager in its safety and health management regulations for construction sites. At the beginning of every fiscal year, the Divisional Manager of the Housing Division formulates an Occupational Health and Safety Policy to provide notification based on circumstances such as the accidents that occurred in the previous period, the state of occupational health and safety promotion as well as compliance with relevant laws. In addition, permeating a safety culture has been designated as a basic policy, and we are working to achieve this in primarily three ways; compliance with the law, promotion of occupation health and safety education and eradication of occupational injuries. Always raising awareness toward the recognition of safety first permeates this safety culture. Offices, branches and building contractors set important management targets for the fiscal year to eliminate five-types of major accidents; falls, accidents with tools, tip-overs, accidents with heavy machines and heat strokes.

Occupational Health and Safety Management System for Construction Sites of Housing Business

- Home

- Sustainability

- Social

- Occupational Health and Safety

- Occupational Health and Safety Management