- Home

- Sustainability Report

- Environmental

- Resource Recycling Initiatives

- Waste Reduction and Recycling

Waste Reduction and Recycling

Basic Policy

The Sumitomo Forestry Group makes efforts in attaining zero emissions and reducing industrial waste generated, at the same time as promoting reuse and recycling for each operational process in accordance with the Sumitomo Forestry Group Environmental Policies in order to build a sustainable and recycling-oriented society. Our priority is to realize a circular bioeconomy by leveraging forests and wood resources, and we are promoting initiatives to reduce environmental impact, such as protecting resources by advocating for recycling and zero emissions. The Sumitomo Forestry Group has also established measures in each of its divisions to achieve these priority targets. We will check the progress of the plan each fiscal year, and by fiscal 2024, the final year of the Medium-Term Management Plan, we aim to reduce the Group's total final processing amount by 5.4% from the fiscal 2021 level, to 19,905 tons.

- Click here for related information

Initiatives to Achieve Zero Emissions

The Sumitomo Forestry Group defines achievement of zero emissions as a recycling rate of 98% or more using no simple incineration or landfill for all industrial waste produced by each business site. Based on this definition, domestic manufacturing facilities achieved zero emissions in fiscal 2009 while new housing construction sites achieved zero emissions in metropolitan areas in fiscal 2012. Our overseas manufacturing plants achieved zero emissions in fiscal 2020.

In addition, we aim to achieve zero emissions through more detailed management by dividing them into seven categories of new housing construction sites, domestic manufacturing plants, power generation business, remodeling and renovation business, lifestyle services business, etc., overseas manufacturing plants, and demolition work sites in consideration of status of business activities and waste generated. Continuing from last year, we achieved zero emissions at our domestic and overseas manufacturing plants and power generation plants in fiscal 2022.

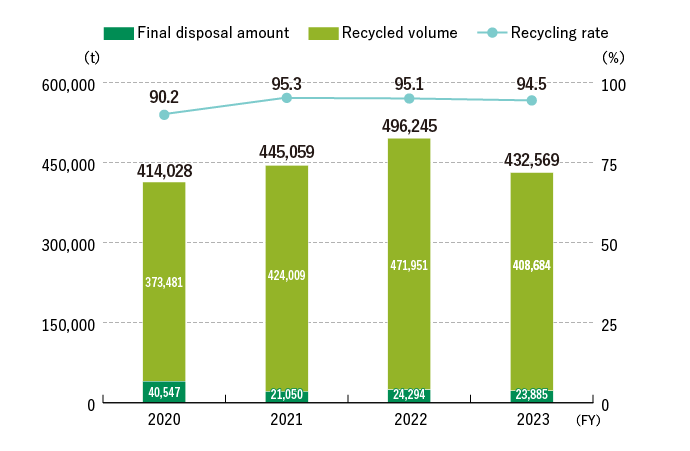

Trends in Waste Generated and Recycling Rate*1 *2

*1 Figures for Cohnan Kensetsu Inc. are included from fiscal 2022

*2 Data collection period for emissions from fiscal 2020 is January to December of each year, and the emissions counting period for fiscal 2019 is April to March 2020

Initiatives for Knowledge Acquisition of Waste Managers

The Sumitomo Forestry Group is taking steps to acquire knowledge so that each person in charge can properly deal with industrial waste generated at construction sites as well as waste generated at offices.

The Housing Division has launched a new e-learning course titled "Key Points for Construction Waste Management," which all managers in charge of production departments at branches must take. In response to stricter regulations on asbestos, we have also established an e-learning course on "Preliminary Investigation of Asbestos" and "Waste Management Basics" to promote the acquisition of knowledge on waste generated from offices. In addition, Sumitomo Forestry distributes a monthly "Safety, Environment and Quality Inspection Department Information" to its branches to keep them up-to-date on the latest information, and also provides guidance and education to construction subcontractors and demolition companies.

Formulating Standards to Handle Plastics

Plastics spread throughout society quickly and brought convenience and other benefits to our lives. However, the reuse and material recycling rate of plastics is still low in the world, compared to other materials. Pollution problems caused by plastics waste flowing into our oceans have become a global issue. The Sumitomo Forestry Group set measures to respond to the issue of plastics in August 2019, and it has been raising awareness in all relevant departments. We are looking into any and all alternatives to plastic goods for novelty item, stationary supplies and even packaging. We have put in place various initiatives from using cans instead of plastic bottles for vending machines and drinks stored at the company unless for a special reason, such as disaster prevention, to not passing out drinks in plastic bottles during meetings. We have also reflected and revised measures for handling plastics in the "Sumitomo Forestry Group Green Purchasing Guidelines".

Compliance with the Plastic Resource Circulation Act

On April 1, 2022, the Plastic Resource Circulation Act came into effect.

This act is designed to promote plastic resource recycling efforts (3R+Renewable) by all entities involved in the design, manufacturing, sale, and supply of plastic products, as well as the discharge, collection, and recycling of waste.

For "high-volume emitting businesses" that emitted 250 tons or more in the previous fiscal year, information on the status of target achievement must also be included and disclosed on the internet or other media (applicable to Sumitomo Forestry, Sumitomo Forestry Home Tech, and Sumitomo Forestry Crest).

Status of Target Initiatives and Measures in Target Divisions

| Division | Project | Indicators for Evaluation | FY12/21 (Results) |

FY12/22 (Results) |

FY12/23 (Estimated) |

|---|---|---|---|---|---|

| Sumitomo Forestry (Housing) |

Emission suppression | Plastic waste emissions (t) | - | Calculation | Consideration of reduction methods |

| Recycling | Continue to promote recycling into solid fuel (RPF), etc. | ||||

| Measure | Emission suppression by studying specific reduction methods, and continue to promote recycling into solid fuels (RPF) and other forms of recycling. | ||||

| Sumitomo Forestry Home Tech |

Emission suppression | Emissions per unit of completed construction | 0.020t/million yen | 0.0297t/million yen | Reduced from the previous fiscal year |

| Recycling | Recycling rate | 85.3% | 81.6% | Reduced from the previous fiscal year | |

| Measure | Regarding the suppression of occurrence, we will discuss the reduction of plastic packing materials from suppliers, and work on the use of on-site reuse of protection materials. As for emission suppression, we will work to change the intermediate treatment contractors with low recycling rates through discussions. | ||||

| Sumitomo Forestry Crest |

Emission suppression | Plastic waste emissions (t) | 226.8t | 235.9t | 225.2t |

| Recycling | Amount of plastic waste landfilled (t) | 5.6t | 2.8t | 1.6t | |

| Measure | As for emission suppression, we will work on to reduce the volume of packing for solid floor spacers, replacement of foam protection materials with paper materials, and the replacement of air cushions. | ||||

- Home

- Sustainability Report

- Environmental

- Resource Recycling Initiatives

- Waste Reduction and Recycling