- Home

- Sustainability

- Environment

- Sustainable Forest Management

- Protecting Domestic Forest Resources

Protecting Domestic Forest Resources

Basic Policy

In recent years, there has been concern in Japan that the deterioration of planted forests such as Japanese cedar and Japanese cypress throughout the country is impairing public benefit of forests, such as water source recharge. It is said that the profitability of the forestry industry has deteriorated due to low lumber prices, which has made it impossible to properly care for the forests, such as by thinning. In order to prevent further devastation of forests by revitalizing the forestry industry, the government of Japan has set a goal of raising wood self-sufficiency rate to roughly 50% by 2025. Sumitomo Forestry will contribute to achieving the Japanese government's goal by expanding the area of managed forests, introducing smart forestry, propagating fast-growing trees, developing afforestation and silviculture technologies, expanding its container nursery business, and promoting solution businesses that utilize ICT.

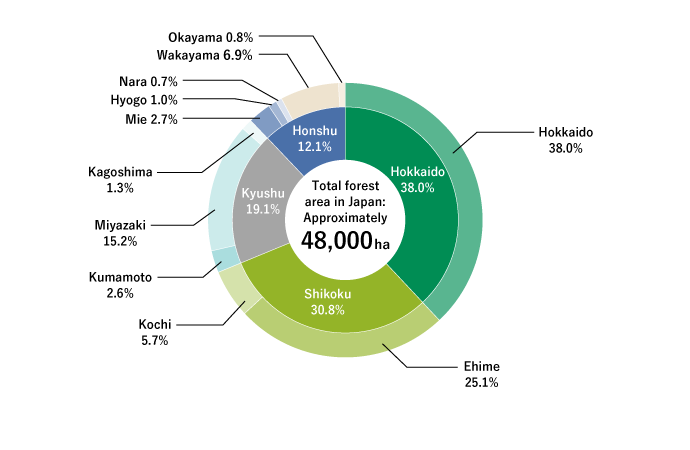

Breakdown of Company-Owned Forests (as of December 31, 2024)

Preserving and Increasing Forest Resources Through Management of Company-Owned Forests

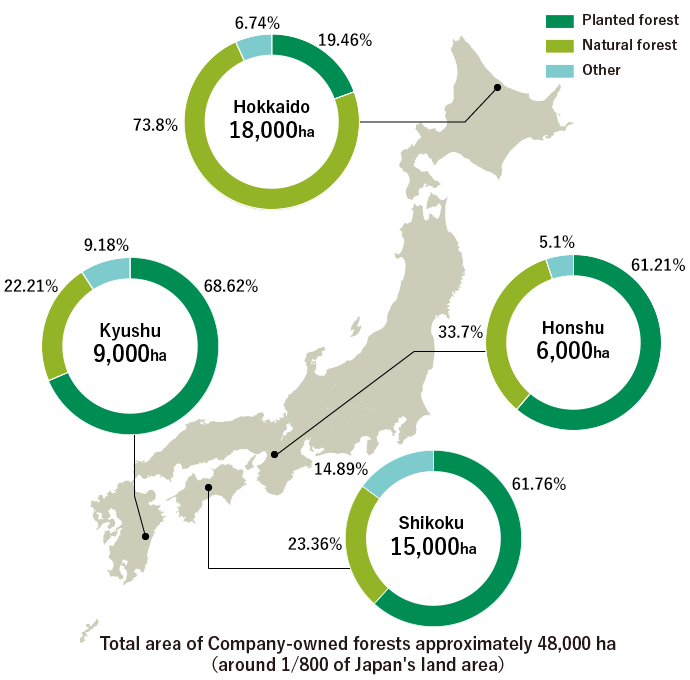

The Sumitomo Forestry Group owns a total of approximately 48,000 ha (about 1/800 of the national land area) of forest land area. Company-owned forests are categorized as either "working forests", where the production of wood is the priority, or "conservation forests", where environmental conservation is the focus.

Sumitomo Forestry acquired a forestry certification from Japan's Sustainable Green Ecosystem Council (SGEC) *1 for all company-owned forests*2 in 2006 and third-party evaluations have confirmed that the forests are being properly managed, including with regard to measures to conserve biodiversity. New forest purchases after the acquisition of the forest certification have each been under evaluation for certification and our certification rate is 100%.

Forest operations include appropriate thinning, which helps to preserve and increase forest resources, while taking into consideration the surrounding environment including the ecosystem. Sumitomo Forestry also aims for highly productive management of its forests based on operational plans that follow the principle of performing the appropriate management for the appropriate tree species on the suited land.

*1Japan's own forestry certification system through which forest management is verified as sustainable by third parties. Certification is based on seven criteria that include the preservation of biodiversity and the conservation and maintenance of soil and water resources. Due to the June 2016 approval of mutual recognition of the PEFC*3 international forest certification system, international recognition has increased

*2The forests owned by Sumitomo Forestry exclude the lands leased to Kawanokita Development Co., Ltd., which is a Group company responsible for operating a golf course, and the surrounding forest. Newly purchased forests are excluded because they underwent expanded inspections during the subsequent fiscal year

*3The Programme for the Endorsement of Forest Certification Schemes is an international NGO that mutually authenticates certification standards created in each country and region as criteria to be shared internationally. 44 national and regional forest certification schemes are mutually recognized with PEFC (from PEFC HP)

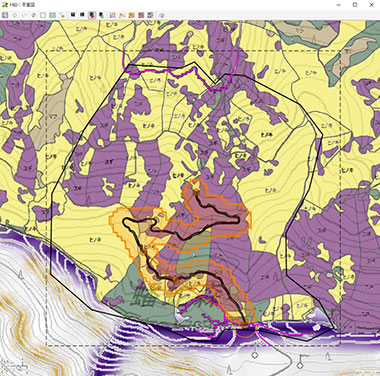

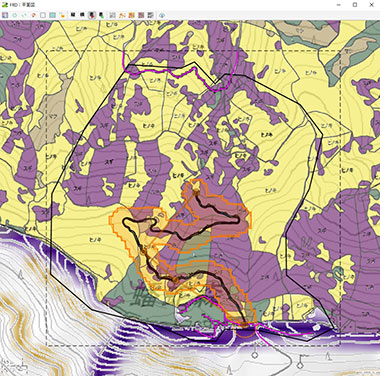

Distribution and Area of Company-Owned Forests (as of December 31, 2024)

Forest Revitalization Initiatives

Seedling Production for Regional Revitalization

An increasing number of municipalities are working to foster forest resources that are not yet effectively utilized and to revitalize the forestry industry as one part of regional revitalization measures. Furthermore, the area of reforestation after clear cutting is increasing as the coniferous trees planted after World War II have entered the harvest season. It is desirable to establish a stable supply system for seedlings, but it is expected that the supply will become insufficient in the future due to a decrease in the number of growers.

Sumitomo Forestry was one of the first companies to modernize containerized nursery seedlings production and began operating facility-based nursery tree production establishments by utilizing its own research and development of production technology. By controlling temperature and humidity in the facilities, we are able to produce seedlings year-round, dramatically increasing production per unit area compared to conventional open-air seedling cultivation. We are also linking to local municipalities to contribute to the revitalization of the region by establishing greenhouses with local employment as well as the development and standardization of new technology related to seedlings cultivation.

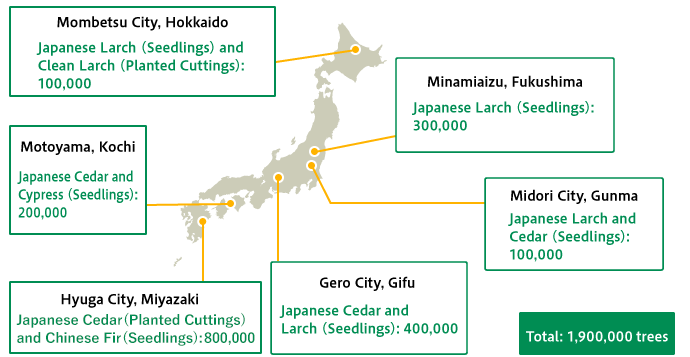

Cultivating Sumitomo Forestry Seedlings Throughout Japan

We opened a facility-based nursery seedlings production establishment in Hyuga City, Miyazaki Prefecture in 2012, followed by the same type of facility in Mombetsu City, Hokkaido. We opened production facilities in Gero City, Gifu Prefecture in fiscal 2016, Motoyama Town, Kochi Prefecture in fiscal 2017, Midori City, Gunma Prefecture in fiscal 2018, and Minamiaizu Town, Fukushima Prefecture in fiscal 2019. Currently, we have a system capable of producing 1.9 million seedlings per year nationwide.

In addition to producing seedlings at our own facilities, in fiscal 2022 we increased the number of trees we contract out for production, strengthening our system for the stable supplies of seedlings. In fiscal 2023, we expanded the development of seed orchards for selected mother trees, and in fiscal 2024, we concluded an agreement with Tokyo Metropolitan Government regarding the production of pollen-free cedar. We accelerated efforts to supply seedlings to meet demand, including countermeasures against pollen.

Sumitomo Forestry's seedlings production systems

Efforts in Fast-Growing Trees

Sumitomo Forestry has begun efforts in fast-growing tree forests that are gaining more attention in recent years. Fast-growing trees are those that grow faster than Japanese cedar and Japanese cypress and can be harvested in a shorter felling season, and include Chinese fir, bead trees, and willow trees.

The Hyuga Forestry Office is conducting test plantings of Chinese fir in company-owned forests in Kumamoto and Miyazaki prefectures. This test monitors aspects that include the reduction in weeding and a growth comparison with Japanese cedar through growth surveys and other research to examine the potential as a new tree species for garden vegetation.

In addition, the Environment and Resources Division and the Tsukuba Research Institute are cooperating to plan the planting of fast-growing broadleaf trees suitable for fuel material.

Chinese fir

Development of a Forestry Transport Drone

Workers are currently carrying seedlings weighing roughly 10 kg on their back when planting Japanese cedar, Japanese cypress and other tree species. Particularly in Japan, the terrain is quite hilly and places a huge physical burden on workers, which makes it difficult to secure a labor force.

That is why Sumitomo Forestry has been advancing the development of drones to transport these seedlings jointly with drone manufacturers and distribution companies that have proven themselves in the agricultural field. Repetitive proof-of-concept tests were conducted in company-owned forests by flying drones safely over complex terrain and in harsh weather to ensure safe drone flight and reliable unloading of seedlings. Based on these tests and various improvements, sales of the Morito Forestry Drone to transport seedlings began throughout Japan in fiscal 2020.

In the course of our sales activities, we have learned that there is a growing need in the field to transport not only seedlings, but also heavy materials such as those used to prevent damage by animals, which has been on the rise in recent years. Accordingly, improvements were made regarding the transportation of forestry materials, and the maximum loading capacity has been increased from 8 kg in the previous model to 25 kg. In fiscal 2024, we produced a promotional video and brochures as part of our initiatives to promote sales.

Forestry transport drone 'morito'

FRD Forestry Roadway Design Support System

Current Status of Strip Road Design in Japan

Forests in Japan often have insufficient forest roads or strip roads in place which prevent smooth management of forests and transport of the wood that is harvested. Currently, when constructing forest roads or strip roads, lines are drawn by hand over a paper topographical map before visiting the site to see if that plan for the road network can be executed according to the proposed alignment. This process of examination is usually done over and over again. The reality is that the process of creating the line drawn plans and checking and verifying on site relies heavily on personal intuition and experience, and takes a great deal of time and labor.

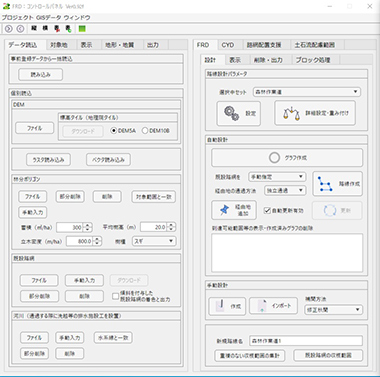

Forestry road networks design using FRD

FRD is a software co-developed with Mr. Hiroaki Shirasawa (currently Forestry and Forest Products Research Institute) to support road network design. It is used to design forest road networks, such forest roads and strip roads after utilizing precise topographic data obtained by airborne laser mapping. The main feature is a function for automatic design able to automatically create the line drawings by inputting the site of departure and destination in the operation screen. This feature creates line drawn plans that can be maintained at low cost based on parameters, including requirements such as longitudinal slope and the curvature radius, width, and operation costs specified in advance. In addition, we have devised a way for software to recognize dangerous terrain. This software packs the right features necessary for the job, such as allowing the design of safety lines that are less likely to break and safer, avoiding potential collapse and other circumstances when creating a plan. The on-site exploration of the line drawn plans for roadways designed in the software offers efficient on-site verification. In fiscal 2023, we upgraded the system to make it more user-friendly by adding a function to analyze amount of resources that can be collected from designed road network. We also held webinars for existing users to introduce good practices and disseminate the new version as follow-up. In the future, we will consider developing enhanced automated design functions that take slope stability into account, features for outputting CAD data formats, and developments aimed at applications for overseas forests.

FRD control panel

Forest road design to avoid dangerous places (in red frame)

Spreading the Use of the Winch-Assist Type Forestry Work Equipment

In fiscal 2023, Sumitomo Forestry demonstrated in Yamanashi Prefecture and Yamaguchi Prefecture a winch-assist forestry machine (tether) it developed jointly with Nippon Caterpillar LLC and other companies using subsidies from Japan Forestry Mechanization Association. In fiscal 2024, demonstrations were conducted in Yamanashi Prefecture and Tochigi Prefecture.

The Tether is forestry machinery that assists heavy equipment for logging and hauling out on sloping terrain, pulling the heavy equipment by wire to maintain a stable posture of the heavy equipment. Forestry operations using heavy machinery will be possible on slopes where heavy machinery could not be used previously, which is expected to improve security and productivity.

We will continue to use the forestry machine to improve the safety of operations on sloping terrain and to realize environmentally conscious forestry.

Work using the Tether

Improvement and Popularization of Remote Clear Underbush Cutters for Forestry Work

In collaboration with the Japan Federation of Forestry Cooperative Associations and the Norinchukin Bank, we are conducting demonstration tests of remote clear underbush cutters for the forestry industry.

The remote type clear underbush cutters reduces the workload of clearing the ground and cutting the undergrowth at the time of planting, and improves work safety by replacing the conventional hand-held type clear underbush cutters. We are working on improving and promoting remote clear underbrush cutters for forestry work. In fiscal 2023, these machines were introduced for operations in our company-owned forests. In fiscal 2024, 65 hectares of site preparation and 45 hectares of underbrush cutting were carried out in our company-owned forests in Mombetsu. Additionally, we participate in the commissioned research consortium of the Fukushima International Research and Education Organization with the aim of developing automated and remote-controlled technologies for site preparations and underbrush cutting.

Work view of remote clear underbush cutters

- Home

- Sustainability

- Environment

- Sustainable Forest Management

- Protecting Domestic Forest Resources