- Home

- Sustainability

- Environment

- Resource Recycling Initiatives

- Resource Circulation within the Sumitomo Forestry Group

Resource Circulation within the Sumitomo Forestry Group

Basic Policy

The Sumitomo Forestry Group makes efforts in attaining zero emissions and reducing industrial waste generated, at the same time as promoting reuse and recycling for each operational process in accordance with the Sumitomo Forestry Group Environmental Policy and the internal Industrial Waste Management Regulations in order to build a sustainable and recycling-oriented society. Our material issue is to realize a circular bioeconomy by leveraging forests and wood resources, and we are promoting initiatives to reduce environmental impact, such as protecting resources by advocating for recycling and zero emissions. The Sumitomo Forestry Group has also established measures in each of its divisions to achieve the material issue. We will check the progress of the plan each fiscal year, and by fiscal 2024, the final year of the Medium-Term Management Plan, we aim to reduce the Group's total final processing amount by 5.4% from the fiscal 2021 level, to 19,905 tons; the actual result was 19,971 tons.

- Click here for related information

Management System

The Sumitomo Forestry Group, based on its Industrial Waste Management Regulations, complies with the Waste Management and Public Cleansing Act and related laws, and is committed to reducing the generation of industrial waste, ensuring proper disposal, and promoting recycling and reuse.

In addition, we have established basic policies on industrial waste management and have taken necessary measures such as developing regulations and building management systems.

As a management organization, we clarify the management system and management responsibilities, and regardless of the scale of each waste-generating site, we require compliance with company policies and regulations. To ensure proper management of industrial waste, we appoint industrial waste managers (including management supervisors, management officers, and, when necessary, special industrial waste managers).

Furthermore, based on the regulations, we implement measures for abnormal situations and provide education and guidance on industrial waste management to employees and contractors.

Risk Management for Waste Management

Construction-related waste makes up the highest percentage of industrial waste that is illegally dumped in Japan. In terms of the breakdown of illegally dumped industrial waste, 72.6%* of the total is construction waste. Viewing the environmental risks presented by the processing of industrial waste as one of the biggest in terms of the potential impact on society and business, the Sumitomo Forestry Group works to ensure that industrial waste is disposed of appropriately.

Specifically, to comply with the Waste Management and Public Cleansing Act and other related laws and regulations, the Group has established a set of industrial waste management regulations covering reduction, appropriate disposal, recycling and reuse of industrial, as well as manufacturing regulations stipulating standards essential for production activities. In keeping with these regulations, voluntary audits of waste manifests and terms of outsourcing agreements with waste processors are carried out twice a year for each Sumitomo Forestry Group company office in Japan emitting industrial waste. If an audit concludes that corrective action is required, appropriate action is taken and it is subsequently confirmed through reports submitted in line with the industrial waste management system that waste is being properly treated.

In addition, industrial waste managers at each office conduct site checks of contractors' waste treatment plants at least once a year. In fiscal 2024, managers from the Housing Division conducted 519 on-site checks at 525 waste treatment plants run by 329 waste treatment contractors. Divisions other than the Housing Division as well as offices of Group companies are being instructed to continue using waste treatment plants which the Housing Division has already inspected. In addition, we have electronically circulated and stored site check records and shared such information since fiscal 2024.

To be able to determine whether industrial waste is being processed in an appropriate manner, Sumitomo Forestry Group asks waste treatment contractors to employ electronic manifests. All branches of the Housing Division as well as all contractors accepting industrial waste from new housing construction sites have already introduced electronic manifests. The adoption rate, including manifests for housing demolition waste, has remained 100% in fiscal 2024 as well.

* From the materials announced by the Ministry of the Environment in 2023

Initiatives to Achieve Zero Emissions

The Sumitomo Forestry Group defines achievement of zero emissions as a recycling rate of 98% or more using no simple incineration or landfill for all industrial waste produced by each business site. Based on this definition, domestic manufacturing facilities achieved zero emissions in fiscal 2009 while new housing construction sites achieved zero emissions in metropolitan areas in fiscal 2012. Our overseas manufacturing plants achieved zero emissions in fiscal 2020.

In addition, we aim to achieve zero emissions through more detailed management by dividing them into seven categories of new housing construction sites, domestic manufacturing plants, power generation business, remodeling and renovation business, overseas manufacturing plants, demolition work sites, and other business in consideration of status of business activities and waste generated. In fiscal 2024, we achieved zero emissions at our domestic manufacturing plants.

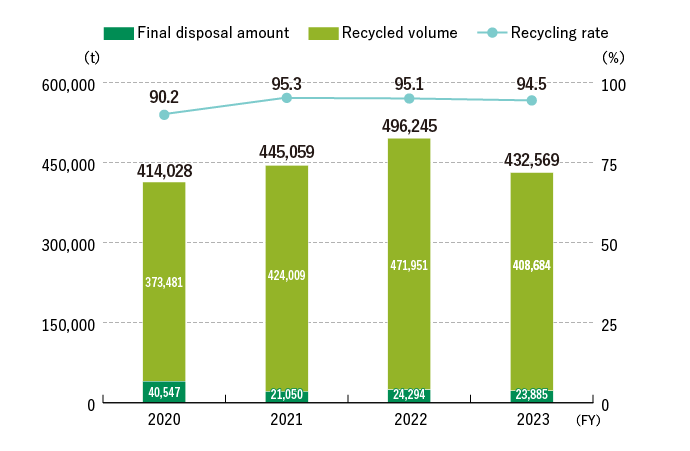

Trends in Waste Generated and Recycling Rate*

* Figures for Cohnan Kensetsu Inc. are included from fiscal 2022

Regular Purchase and Use of Recycled Products

At Sumitomo Forestry Home Tech, wood waste generated at renovation sites is entrusted to waste disposal contractors. The particle boards made from material recycling by these contractors are regularly purchased and used as protective materials for floors at other renovation sites.

Education on Waste Management

The Sumitomo Forestry Group is taking steps to acquire knowledge so that each person in charge can properly deal with industrial waste generated at construction sites as well as waste generated at offices.

For example, training is also provided for employees who coordinate the processing of industrial waste. In fiscal 2024, 88 persons participated in online training at Group companies in Japan, including newly appointed personnel in charge of industrial waste treatment operations and those responsible for industrial waste management. In addition, technical new employees and newly appointed production managers in the Housing Division undergo our original training program on industrial waste management.

Furthermore, we also conduct education using e-learning. In April 2020, the Sumitomo Forestry Group created an e-learning program on basic waste management to teach the fundamentals of managing waste from offices, including industrial waste, and built a system for employees to undergo this curriculum via the intranet. Additionally, starting in January 2025, an introductory e-learning course titled "Introduction to Waste Management" was launched to enable employees to acquire general knowledge about waste management. Furthermore, starting in 2025, content related to waste management was incorporated into the mandatory e-learning courses for all employees of the Sumitomo Forestry Group.

In addition, production managers in the Housing Division are required to complete the e-learning course "Key Points of Construction Waste Management" and pass the associated test to acquire necessary knowledge for their duties. Furthermore, in response to strengthened regulations on asbestos, the e-learning course 'Preliminary Survey on Asbestos' has been established to promote knowledge acquisition. Furthermore, we also provide education on waste management to external parties. The Housing Division distributes a monthly "Safety, Environment and Quality Inspection Department Information" to its branches to keep them up-to-date on the latest information, and provides guidance and education to construction subcontractors and demolition companies accordingly.

Promotion of Green Purchasing

The Sumitomo Forestry Group promotes activities that contribute to the realization of a sustainable society across all business processes—including product and service development, design and production, material procurement and logistics, and waste management—in accordance with the Sumitomo Forestry Group Environmental Policy. As part of these efforts, in 2006 we established the "Green Procurement Guidelines" with the aim of prioritizing the purchase of environmentally friendly products and services in our business activities, and engaging all Group employees in environmental conservation efforts. For office supplies, Sumitomo Forestry's green purchasing rate for fiscal 2024 was 63.9%, a decrease of 1.6 percentage points compared to 65.5% in fiscal 2023.

Initiatives on Plastics

Formulating Standards to Handle Plastics

Plastics spread throughout society quickly and brought convenience and other benefits to our lives. However, the reuse and material recycling rate of plastics is still low in the world, compared to other materials. Pollution problems caused by plastics waste flowing into our oceans have become a global issue. The Sumitomo Forestry Group set measures to respond to the issue of plastics in August 2019, and it has been raising awareness in all relevant departments. We are looking into any and all alternatives to plastic goods for novelty item, stationary supplies and even packaging. We have put in place various initiatives from using cans instead of plastic bottles for vending machines and drinks stored at the company unless for a special reason, such as disaster prevention, to not passing out drinks in plastic bottles during meetings. We have also reflected and revised measures for handling plastics in the "Sumitomo Forestry Group Green Purchasing Guidelines".

Compliance with the Plastic Resource Circulation Act

On April 1, 2022, the Plastic Resource Circulation Act came into effect.

This act is designed to promote plastic resource recycling efforts (3R+Renewable) by all entities involved in the design, manufacturing, sale, and supply of plastic products, as well as the discharge, collection, and recycling of waste.

For "high-volume emitting businesses" that emitted 250 tons or more in the previous fiscal year, information on the status of target achievement must also be included and disclosed on the internet or other media (applicable to Sumitomo Forestry, Sumitomo Forestry Home Tech, and Sumitomo Forestry Crest).

Status of Target Initiatives and Measures in Target Divisions

| Division | Project | Indicators for Evaluation | FY12/23 (Results) |

FY12/24 (Results) |

FY12/25 (Estimated) |

|---|---|---|---|---|---|

| Sumitomo Forestry (Japan Housing Business) |

Emission suppression | Plastic waste emissions | 286 kg/building | 293 kg/building | 292 kg/building |

| Recycling | Continue to promote recycling into solid fuel (RPF), etc. | ||||

| Measure | In December 2024, Sumitomo Forestry began testing the installation of precut underfloor thermal insulation materials. The company plans to gradually introduce the method by area and aims to apply it to all units by summer 2026. The initiative is expected to reduce plastic waste by approximately 40 kg per unit. This effort contributes to the reduction of plastic industrial waste emissions. | ||||

| Sumitomo Forestry Home Tech |

Emission suppression | Emissions per unit of completed construction | 0.0216t/million yen | 0.0176t/million yen | 0.0168t/million yen |

| Recycling | Recycling rate | 82.5% | 85.6% | 86.0% | |

| Measure | Regarding the suppression of occurrence, we will discuss the reduction of plastic packing materials from suppliers, and work on the use of on-site reuse of protection materials. Regarding recycling, we will strive to further improve recycling rate by discussing disposal methods, etc. with intermediate treatment contractors. | ||||

| Sumitomo Forestry Crest |

Emission suppression | Plastic waste emissions (t) | 227.8t | 262.2t | Reduced from the previous fiscal year |

| Recycling | Amount of plastic waste landfilled (t) | 98.7% | 99.5% | Improved from the previous fiscal year | |

| Measure | Regarding suppression of occurrence, we will work to reduce in-process spoilage and number of returned products due to mistakes in arrangements. To reduce emissions, we will reduce amount of packaging materials by consolidating number of product parts and packing materials. | ||||

- Home

- Sustainability

- Environment

- Resource Recycling Initiatives

- Resource Circulation within the Sumitomo Forestry Group