- Home

- Sustainability

- Governance

- Business Continuity Management

Business Continuity Management

- Business Continuity Management System

- Resilience Certification

- Ensuring the Safety of Employees

- Initiatives for Continuity of Critical Operations

- Training and Education Activities

- Disaster Prevention and Reduction Countermeasures

- Strengthening Supply Chain Business Continuity Plan

- Continuity of Customer Service

Business Continuity Management System

The Sumitomo Forestry Group has established BCM Subcommittee in order to respond to business interruption risks, such as natural disasters and infectious diseases, which are extremely difficult to prevent through corporate efforts and may have a significant impact on functions of the head office. We disseminate and strengthen the Business Continuity Management System (BCM system). And we also formulate, review, and improve the Business Continuity Plan (BCP), or conduct training based on the plan.

In fiscal 2024, the BCM Subcommittee was held twice. We inspected the status of business continuity systems at Group companies and worked to promote further development of these systems based on the inspection results.

Resilience Certification

In July 2021, the Sumitomo Forestry acquired "Resilience Certification" (Resilience Certification for contribution to national resilience)*, which is given to business operators who are actively engaged in business continuity and social contribution. In 2019, we formulated BCM Regulations and have been working to review and improve the BCM system. In addition, since the Great East Japan Earthquake, through the Wooden Home Builders Association of Japan, to which we belong, we have concluded agreements on disaster prevention and reduction with local governments around the country, and we were recognized for working to revitalize local communities and solve social issues in addition to creating safe and secure communities. In July 2023, we were awarded renewal of this certification in recognition of the ongoing efforts. We will continue to accelerate our efforts to increase resilience in order to minimize the impact of business disruptions and recoveries from major disasters and pandemics.

* A system in which the Association For Resilience Japan examines and certifies businesses that are actively engaged in business continuity initiatives based on the "Guidelines for Certification of Organizations Contributing to National Resilience" established by National Resilience Promotion Office, Cabinet Secretariat.

Ensuring the Safety of Employees

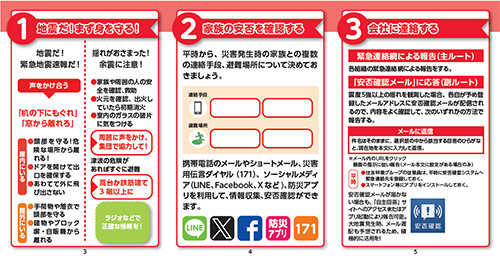

The Sumitomo Forestry Group places the highest priority on ensuring safety of employees and their families as a principle of response in the event of an emergency. Therefore, we have established an emergency communication system for each organization. In addition, we have introduced a safety confirmation system that automatically transmits information in conjunction with disasters to each Group company in Japan. Every year, Group companies in Japan conduct safety confirmation drills. A total of 16,517 employees participated in 2024.

To ensure safety of our overseas employees, we introduced a safety confirmation system for overseas employees in 2019. This system enables us to quickly confirm their safety in the event of an emergency such as an earthquake, terrorist attack, or volcanic eruption in the host country.

In addition, we are striving to prevent secondary disasters due to insufficient information by operating a crisis management portal site (BCPortal) that can be accessed from external networks as a tool for disseminating information from the company after a disaster has occurred, and by building a system in which employees and their families can obtain various information even in the event of an emergency.

Initiatives for Continuity of Critical Operations

At Sumitomo Forestry, the BCM Regulations assume both a crisis event that may result in the suspension of head office functions and a crisis event that may simultaneously cause damage affecting the residential safety of a large number of homes. Based on these assumptions, the Company has formulated a Business Continuity Plan (BCP). This BCP specifies key operations, such as confirming the safety of employees and their families and making various payments. It also includes measures such as establishing a system that enables the continuation of important operations at two bases—Tokyo and Osaka—and conducting remote backups of various systems and data necessary for carrying out operations in the event of an emergency.

Training and Education Activities

At each disaster site, even in a situation where the chain of command with the head office is disconnected, it is necessary for the responsible person to make flexible decisions and quickly take initial actions. Therefore, "Simulated Initial Response Training" is implemented to enhance response-ability. This training has been implemented since 2011. The training was implemented for a total of 53 operational managers of different sites in 2022. In 2024, in line with the appointment of an Executive Officer in charge of the Osaka Head Office (BCM), two emergency disaster response drills were conducted at the Osaka Temporary Disaster Response Headquarters, focusing on initial response actions in the event of a crisis.

Disaster Prevention and Reduction Countermeasures

In preparation for those who have difficulty returning home in the event of a major earthquake, we have established a minimum common standard disaster prevention stockpile at each workplace at all Group sites in case they are required to stay at the office or walk long distances home. In particular, in major urban areas (Tokyo metropolitan area, Osaka city, Nagoya city, and government-designated cities) where a large number of people are anticipated to be unable to return home, we store emergency supplies in anticipation of three days of work stays.

Strengthening Supply Chain Business Continuity Plan

To prepare for potential disruption of its housing business supply chain following a disaster, Sumitomo Forestry shares the specifications and processes for property construction along with site progress status information with business partners including component makers and building contractors. By enabling advanced procurement of materials and production in this way, the Company is striving to reduce the risk of a disruption to operations. However, there were some delays in material procurement and constructions due to the worldwide spread of the COVID-19 in 2020.

In light of this situation, if a supplier is affected by an earthquake or other natural disaster or other accident such as fire, we ask the supplier about the extent of damages and make every effort to continue supply. We will now explore ways to reinforce this system, including systemization for more quickly ascertaining the actual situation at the affected suppliers. In addition, Sumitomo Forestry works to build a purchasing system which has at least two companies that can supply the same materials as a general rule to ensure readiness for these types of unforeseen situations (including at least two production sites for the same materials).

To address delays in procurement materials, we are having continuous discussions with suppliers. As a short-term measure, we are increasing inventory at suppliers where delays have occurred. As a medium- to long-term measure, we are working to reduce risk by decentralizing production facilities—for example, by establishing production sites in multiple countries rather than relying on a single country.

Sumitomo Forestry also reviews its suppliers of materials, with supplier evaluations conducted every year for determining whether to continue business with them. Business continuity items, such as systems for ensuring alternative supply routes during a disaster, have been added to these evaluations. These efforts will work to further reduce risks that may interrupt business operations in the future.

Continuity of Customer Service

Sumitomo Forestry has setup call centers in Tokyo and Okinawa, thereby facilitating 24-hour after-sales service. (These services entail various consultations including home maintenance/repairs accepted 24 hours a day 365 days a year.)

Sumitomo Forestry has also developed a mechanism whereby any call center can back up the functions of another call center in the event it is affected by a disaster. Through a unified emergency system, the Company can share damage information pertaining to owners nationwide, enabling us to respond quickly to disaster and requests for repairs.

- Home

- Sustainability

- Governance

- Business Continuity Management